The fruit and vegetable drying machine is a food dehydrator specialized in drying all kinds of fruits and vegetables. It mainly uses a fan to circulate hot air inside the machine to dehydrate fruits and vegetables. It applies to drying food, vegetable, medicine, herbs, spices, fruits, etc., and it is a very important machine in our daily life. Until now, we have developed 3 types of fruit and vegetable dryer machines. They all adopt hot air circulation mode. Industrial vegetable and fruit dryer machines are widely applied in medicine, chemical, food, agricultural and sideline products, aquatic products, and light industries.

Commercial fruit and vegetable drying machine development trend

The working principle of the dryer is to dehydrate and dry high-humidity material. It can dry materials of various shapes and has a wide range of applications in the industry. After drying, the waste materials are converted into usable resources, recycling and reuse, energy-saving, and emission reduction. And it can achieve the sustainable development strategy of practicing the scientific development concept.

The importance of a fruit and vegetable dryer

The water content of fresh fruits and vegetables exceeds 80%, and they are prone to spoilage and rot if they are not handled properly during transportation, storage, and sales. There are three ways to store fruits and vegetables: can storage, frozen storage, and dry storage.

And dry storage is the most economical way to store. It adopts a drying and dehydrating way to reduce the moisture content of fruits and vegetables below the safe storage moisture content. It can effectively prevent the growth of microorganisms, delay and reduce the decay reaction with moisture as the medium, extend the storage time, reduce weight, and facilitate packaging and transportation.

Industrial fruit and vegetable dryer machine classification

Type 1 Small stainless steel fruit drying oven

A small stainless steel dryer is also called a hot air circulation fruit and vegetable drying machine. It is universal drying equipment. It has a wide range of applications and is widely used in the heating, curing, drying, and dewatering of materials and products in the pharmaceutical, chemical, food, light, and heavy industries.

Hot air circulation vegetable drying machine technical parameters

| Technical |

Specification | |||||

| Cart | 0 | 1 | 2 | 4 | 6 | 8 |

| Number of pallets | 24 | 24 | 48 | 96 | 144 | 192 |

| Capacity(kg/time) | 60 | 60 | 120 | 240 | 360 | 480 |

| Power(kW) | 6-9 | 6-9 | 15 | 30 | 45 | 60 |

| Fan power(kW) | 0.45 | 0.45 | 0.45 | 0.45*2 | 0.45*3 | 0.45*4 |

| Volume(㎡) | 1.3 | 1.3 | 2.6 | 4.9 | 7.4 | 10.3 |

| Size (mm) | 1410*1200*2140 | 1410*1200*2140 | 2250*1200*2160 | 2250*2160*2160 | 3290*2160*2200 | 4360*2160*2270 |

| Tray size(mm) |

640*640*45 | |||||

| Cart size(mm) |

940*700*1420 |

Features of stainless steel fruit and vegetable drying machine

1. Adopt high-quality stainless steel, with high corrosion resistance;

2. There are two heating methods: electric heating and steam heating, customers can choose according to the situation;

3. The electric heating machine adopts durable quartz infrared heating tube, and the steam type adopts an energy-saving copper radiator. It has a long service life, high thermal efficiency, and will not damage the raw materials;

4. This fruit and vegetable drying machine can dry materials regularly;

5. Large storage capacity, low noise, and fast heating. The processed material is fluffy and soft.

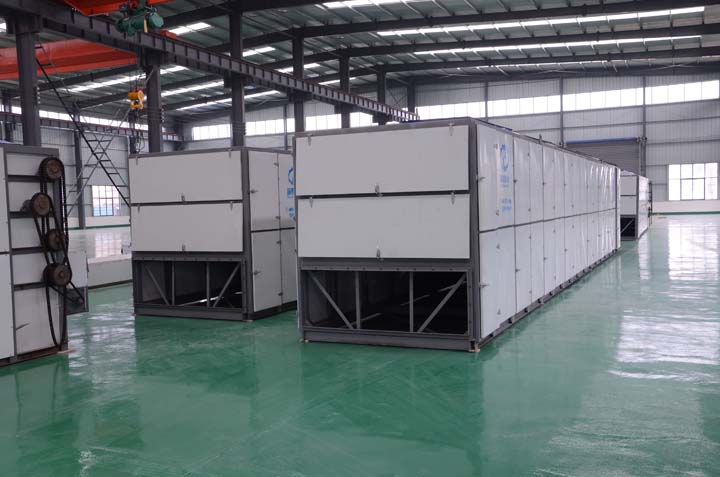

Type 2 Box dryer

Box dryer is also a kind of fruit and vegetable drying machine that has been widely used in recent years. The box-type vegetable and fruit dryer is a closed-drying box with hot air circulating in the box. It adopts the forced air circulation of the fan to reduce the temperature difference between the upper and lower sides of the dryer. The hot air directly contacts the material without additional heat loss. The air in the furnace and the corresponding container do not generate heat, so the thermal efficiency is extremely high. In addition, the machine contains a temperature sensor, which can automatically sense the temperature in the box and keep the temperature in the box at a constant temperature.

Box-type food dryer technical parameters

| Model | Size(L*W*H)(mm) | Drying car number | Capacity(kg/times) |

| TZ-2 | 4000*1600*2500 | 2 | 600 |

| TZ-4 | 6000*1600*2500 | 4 | 1200 |

| TZ-6 | 7200*2300*2500 | 6 | 1800 |

| TZ-8 | 8800*2300*2500 | 8 | 2400 |

| TZ-10 | 10000*2300*2500 | 10 | 3000 |

| TZ-12 | 10500*3300*2500 | 12 | 3600 |

| TZ-14 | 11000*3300*2500 | 14 | 4200 |

| TZ-16 | 11500*3300*2500 | 16 | 4800 |

| TZ-18 | 12500*3300*2500 | 18 | 5400 |

| TZ-20 | 13500*3300*2500 | 20 | 6000 |

| TZ-22 | 14500*3300*2500 | 22 | 6600 |

| TZ-24 | 15500*3300*2800 | 24 | 7200 |

Advantages of fruit and vegetable drying machine

1. The heating is uniform, and the fan-forced air circulation makes the hot air uniform in the box and reduces the temperature difference between upper and lower.

2. High efficiency and energy-saving, hot air directly act on the material without additional heat loss, so the thermal efficiency is extremely high.

3. The temperature and humidity in the drying box are automatically controlled to ensure the proper temperature and humidity required for drying.

4. Adopt low-humidity constant temperature drying, good drying effect, high quality, and good color of dried products.

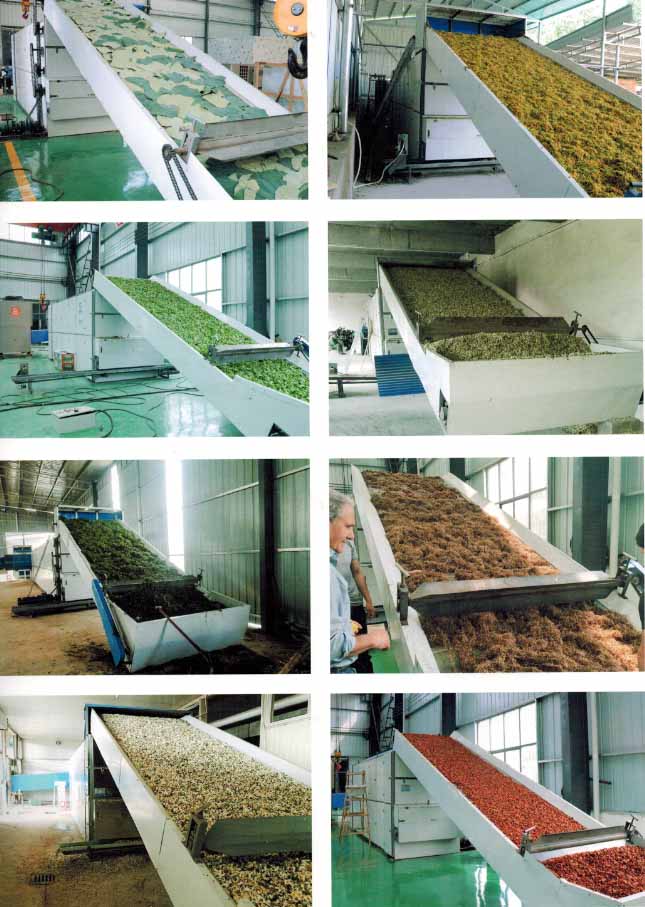

Type 3 Mesh belt vegetable dryer

The mesh belt vegetable dryer equipment can automatically feed and discharge materials. The material moves slowly from a high place to a lower part in the closed box. At the same time, the fan blows in hot air evenly, so that the hot air circulates in the box to dry the material. The dryer can set the drying temperature and drying time. And the indoor temperature is kept constant. The dryer has a high degree of automation and closed operation, which can meet the needs of continuous mass production.

Industrial fruit dehydrator machine technical parameter

| Model | 1.2*8M | 1.2*10M | 1.6*8M | 1.6*10M | 2*8M | 2*10M |

| Belt width(m) | 1.2 | 1.2 | 1.6 | 1.6 | 2 | 2 |

| Length of drying section(m) | 8 | 10 | 8 | 10 | 8 | 10 |

| Paving thickness(mm) | 10-50 | 10-50 | 10-50 | 10-50 | 10-50 | 10-50 |

| Operating temperature(℃) | 50-120 | 50-120 | 50-120 | 50-120 | 50-120 | 50-120 |

| Water evaporation(kg/h) | 100-250 | 120-350 | 110-320 | 140-400 | 150-450 | 200-550 |

| Total power(kW) | 21.2 | 21.2 | 21.2 | 22.7 | 22.7 | 22.7 |

| Size(L*B*H) | 11*1.6*2.7 | 12.5*1.6*2.7 | 11*2.0*2.7 | 12.5*2.0*2.7 | 11*2.4*2.7 | 12.5*2.4*2.7 |

| Weight(kg) | 3800 | 4780 | 4400 | 5550 | 5350 | 6800 |

Best fruit dryer machine suitable raw material display