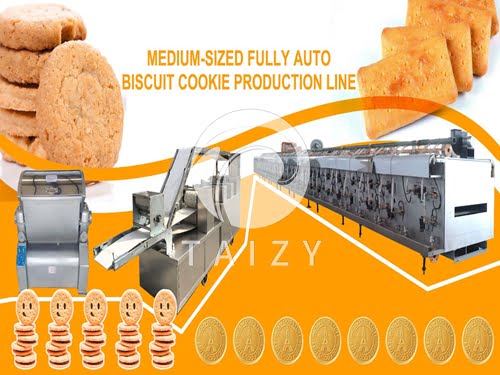

The fully automatic biscuit production line includes automatic biscuit processing machines, which is mainly to produce biscuit. The automatic biscuit making plant machine includes a dough mixer, biscuit forming machine, baking machine, and biscuit packing machine. All biscuit making machines are controlled by CPU module control and driven by a back mounting motor. The whole biscuit production line has the characteristics of compact structure and high degree automation. It can complete the entire biscuit manufacturing process automatically at one time from dough feeding to oil spraying.

Large scale biscuit production line working video

Application of Biscuit Production Line

The fully automatic biscuit production line can accomplish the whole biscuit processing procedure with stable performance. It has various biscuit molds, such as round, square, oval, finger-shaped. Also, the biscuit molds can be customized according to the customer’s production requirement. And we also can provide customers with biscuit baking formulas.

By changing the biscuit mold and formula, customers can produce a variety of popular market hot selling biscuits. Such as cream flavor biscuits, wheaten biscuits, cream cookies, sea-salt flavor cookies, milk flavored biscuits, sesame biscuits, animal-shaped biscuits, vegetable flavor biscuits

Biscuit manufacturing plant layout

There are various types of biscuits on the market. Different types of biscuits have different production processes. But most biscuit production roughly includes dough mixer, biscuit forming machine, baking machine, and biscuit packing machine.

Dough mixer

A dough mixer is a machine that mixes flour, sugar, water, and other raw materials together. The machine can automatically mix raw materials into the dough, reducing labor intensity. If you want to produce biscuits with different flavors, you can add suitable raw materials for flavoring.

Biscuit forming machine

The biscuit forming machine is an indispensable machine in the biscuit production line. It is a machine that presses the reconciled dough into a biscuit shape. The biscuit making machine is mainly formed by pressing the mold on the machine. Therefore, the machine can make different shapes of biscuits by changing different molding dies.

Baking equipment

After molding, it needs a baking machine to bake the raw biscuits to mature. Common biscuit baking machines on the market include hot-air rotary ovens and tunnel baking machines. The hot air rotary oven mainly applies in the small scale biscuit production line. In the large-scale biscuit production plant, it generally adopts a tunnel-type baking machine.

Biscuit packaging machine

After baking and cooling, it needs to pack by a biscuit&cookie packaging machine and then circles into the market. The biscuit packaging machine can achieve multiple styles of packaging, such as individual packaging, two or three per bag, etc.

The above biscuit making machines are not the basic configuration for biscuits production. You can send us pictures of your biscuits or tell us about your production process. We will match you with a suitable machine according to your production requirements.

Fully automatic biscuit production line advantage

- Taizy’s large capacity biscuit manufacturing plant is designed and developed after many years of research and development, integrating with experience and customers’ feedback.

- Itis carried out by mechanical and electrical control from mixed feeding to biscuit molding, biscuit tracking, scrape dough reuse, continuous baking, glazing, cooling, etc.

- All operations are completed automatically, and the thickness of biscuits can be adjusted by manipulating the sheeting pressure.

- Roller sheeting molding is accomplished within one time. The biscuit molding rate is high and the biscuit molding quality is over average.

- It is easy to replace product specifications by changing the impression roller.

- The biscuit baking oven can be assembled in sections for easy installation and transportation.

- The baking oven equips with a mesh belt conveyor to track products.

- It ensures a clean and sanitary baking effect.

- The oil sprayer nozzle adopts a frequency converter for speed control. The spraying speed is stable and the energy-saving effect is good.

10. Mechanical transport speed can be manipulated faster or slower.

- The cookie production line equips with a speed regulating device, fully automatic temperature control, automatic leakage or power failure alarm, and a series of advanced safety devices.

- All parts of the whole machine contacting with raw material adopt stainless steel, meeting the hygienic requirements of the food.

- Novel design, compact structure, and a high degree of automation.