Almond slicer machine is also called nut slicing machine, and it is widely applied to slice peanut, almond, walnut, cashew, etc. The sliced nut pieces can sprinkle on the surface of biscuits, ice cream, cake, bread, which will make their taste better. Therefore, the almond slicer cutting machine is suitable for the food processing industries and the pre-processing of jam, moon cake, and other raw materials. In addition, its price is reasonable, and everyone can afford it.

Almond slicing machine working video

Parameters of the almond slicer cutting machine

| Model | TZ-QP |

| Voltage | 220/380V |

| Dimension | 1000*800*1100mm |

| Power | 2.2KW |

| Cutter wheel speed | 0-600rpm/min |

| Capacity | 300kg/hr |

| Weight | 170kg |

| Slice thickness | 0.5-1.2mm |

Since this nut slicer has a wide range of applications. Therefore, it has a wide range of slices, 0.5~1.2mm. The size of the cut nuts can be customized. Remember that a machine can only cut one size of nuts.

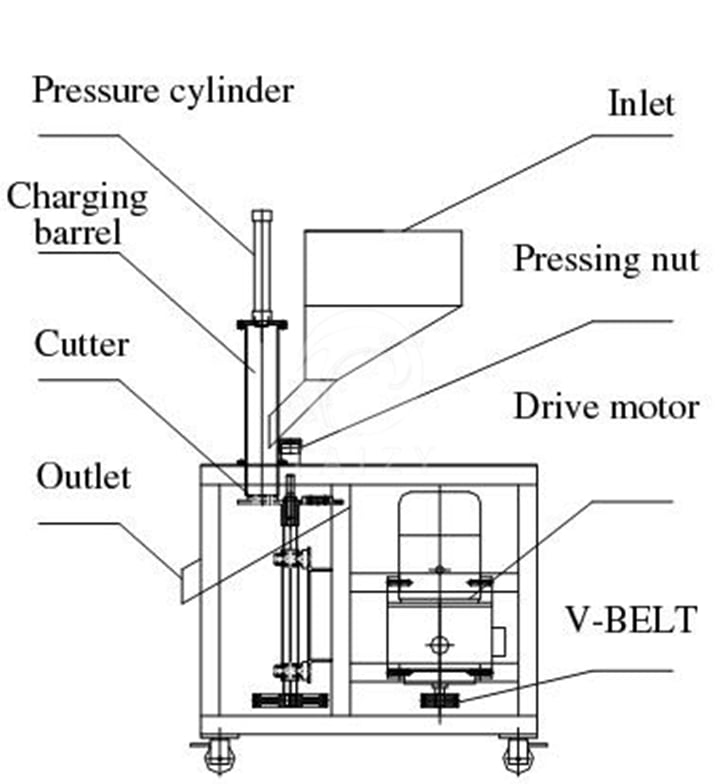

Working principle of almond slice cutting machine

The almond slice cutting machine contains a pneumatic feeding device and a slicing device. The peanut and nuts are placed in a trough, and the peanut and nuts are pressed into the cutter by a pneumatic device to cut out the thin piece of the peanut and nuts. The high-speed peanut and nuts cutting machines are specialized for various nuts slicing.

Advantages of the almond nut slicer machine

- Almond slicer is made of stainless steel which meets food hygiene requirements.

- The parts in contact with the raw material are food-grade stainless steel.

- The blade is made of high-quality high-speed steel, with sharp edges and long service life. It not only can be used for peanut slices, but also almonds, cashew nuts, walnut kernels, hazelnuts, and other nuts slices.

- It has the functions of moisture-proof, dust-proof, oil-proof and safety. peanut almond slicer can be customized for different capacities.

- The machine has compact structure, effective and durable, simple operation and high output. It has a universal wheel for easy movement and a small footprint for a variety of processing

plants.

- The slicing thickness of nut cutting macihine can be adjusted according to customer need to meet different requirements of use.

- The motor adopts frequency conversion speed regulation to adjust the slice output; the mechanism uses a pneumatic device to adjust the pressure to achieve the best slicing effect.

- The price of peanut cutting machine is reasonable.

The preoccupation of peanut almond slicer machine

- the raw material to be sliced can not be too dry. If yes, they should be soaked firstly and then dried to slice.

If the peanut is too dry, the pieces are easily broken. If the water content is too high, the pieces may accumulate on the cutter head and the discharge port.

- The nuts must be selected and processed, which can not be mixed with sand and stones or other debris, otherwise, it will cause the blade edge to collapse.

- The working pressure of the cylinder of almond slicer machine can not be adjusted too high, and should be controlled at 0.3-0.4Mpa. If the pressure is too low, the pieces will be broken. If it is too high, the cutter will vibrate and make the slice thickness uneven.

The installation of peanut almond slicer machine

- Turn on the power and pay attention to whether the spindle cutter is turning clockwise. The motor of the almond slicer machine is an electromagnetic speed-regulating motor. The speed of the cutter head can be adjusted according to the actual requirements of the material.

- You shall note that the speed controller should be returned to the zero position each time when the machine is turned on or off, which can avoid the damage to the speed controller.

- Connect the gas source, connect the clean compressed air from the pressure regulating valve with the 8mm outer diameter air pipe, and adjust the air pressure to 0.3-0.4Mpa.

- you can change the working frequency of the cylinder. Generally, the lifting time of the cylinder is generally 3-4 seconds. The pressing time is generally adjusted to 15-30 seconds according to different thickness and cutter speed, and itis based on the time when the nuts can be fully cut.

- Adjust the thickness of the slice. The operator places the selected and cleaned nuts into feeding hopper to continuously cut them. When adjusting the thickness, you can loose the lock nut, and the handle is adjusted clockwise to increase the thickness. Conversely, the thickness is reduced. The thickness is 1.5 mm when the lock nut is rotated for one circle. It also can be adjusted as required. After adjusting, you should re-lock the nut.

- Replace the blade. This almond slicer machine is equipped with two high-speed steel blades on the rotary cutting disc. When the blade edge is blunt and not sharp or when the nuts are mixed with sand and small stones, the blade must be replaced in time.

What should be noted during operation?

When changing the blades, open the front panel of the discharge port and the round cover on the almond slicer surface. Remove the two M6 bolts on the blade from the underside of the rotary cutter by using a hexagon socket bolt wrench. Finally, reinstall the new blade.

Peanut almond slicer is widely used in food processing. We can provide an instruction manual when the machine is sent. We also have many peanut processing machines. Like peanut peeling machines, peanut roasted machines, and so on. If you need a production line, we can customize it for your requirements.

FAQ of almond slicer machine

What is the raw material?

It can be peanut, almonds, cashew nuts, walnut kernels, hazelnuts, and other nuts.

Can I adjust the thickness of the pieces?

Yes, it can be adjusted.

Why do the final pieces contain some sands or other debris?

The blades inside are blunt, and they should be replaced in time.

How to adjust the thickness of pieces?

Loose the lock nut and rotate it to increase or reduce the thickness.

Is there any requirement for the nuts before working?

Yes, the nuts can not be too dry or wet.