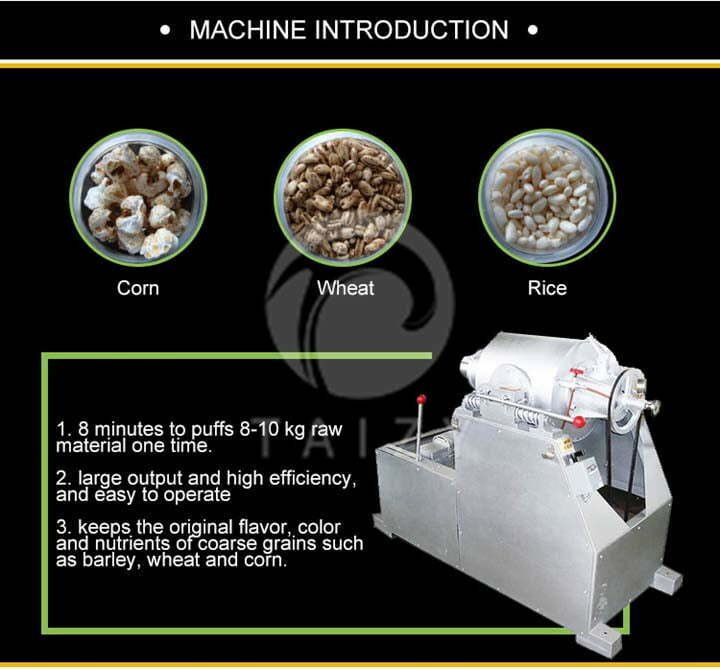

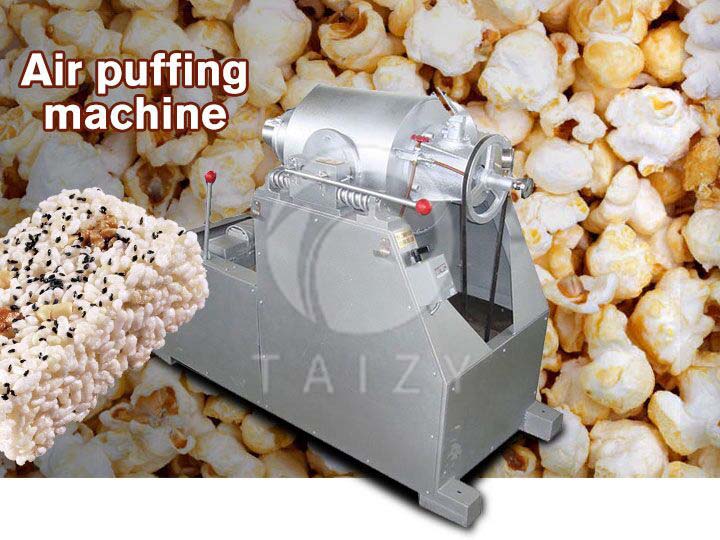

The air puffing machine is to produce puffed food, adopting gas heating, and the raw material can be soybean, corn, rice, wheat and all kinds of nuts. It bears high output, low energy consumption and high working efficiency. In addition, we conduct rigorous testing before delivering the machine.

Operation video of airflow grain puffing mahcine

Technical parameters of rice wheat bulking machine

| Power supply | single-phase 220V |

| Power capacity | 0.75KW |

| Capacity | 50-60kg/h |

| Curb weight | 450kg |

| Size | 1650×800×1350mm |

How to operate air puffing machine?

1. Before working, operator should lubricate driving part and check whether be operating component is loose or not.

2. During the first puffing, the popcorn bulking machine should be heated to 120 ° C and then shut down. The raw material can mixed with 50g edible talc. Note: The requirements of raw material: no debris, and moisture content is less than 15%

3. loading procedure: loading → cover → tighten the lid →heating

4. Loading: Loosen the handle outward-turn the hand wheel to make the bottle turn up 45°-pour the material-close the lid-reset the hand wheel- lock it to heat.

5. During the heating process, turn on the drum switch every 3~4 minutes to change the direction to make the material heating more evenly.

6. According to the difference of raw material, you shall choose fire extinguishing with appropriate pressure (normally 8kg rice, 10kg corn). What’s more, to reach best puffing effect, the fire time is also different.

How to discharge the puffed food?

1. Pull the buffer bracket under the pot.

2.close and lock the gas to turn off the fire.

3. The operator must stand on the right side of the machine, using a special wrench to move the handle.

4. Remove excess residue from the pot after operation.

Note: Discharge procedures are very important, and operator should pay attention to it.

The precautions of air puffing machine

- If the cover can not be tightened, the seal must be replaced.

- There air puffing machine must be fitted with a reference ground conductor to prevent leakage.

- When a liquefied gas pipe leak is detected, the machine must be stopped and the main valve should be closed after the inspection.

- When the wheat bulking machine is working, people cannot stand in front of it.

- During operation, there is much noise, and it is necessary to soundproof.

- In normal production, the rotary bearing needs to be lubricated once (heat resistant 500 ° C).

Method: use oil gun to press some grease into the feeding cup, and add a small amount of lubricant to each rotating part

Detailed information about each spare parts.

| Parts Description | ||

| 1 | handwheel | use for loading and unloading |

| 2 | Thermometer | show the tank’s temperature |

| 3 | Pressure Gauge | show the tank’s pressure |

| 4 | Grease | filling high-temperature grease |

| 5 | LPG valve | open and close the LPG |

| 6 | Rotating locking handle | forward is the locking.back is to open the lock |

| 7 | Rotating locking handle | pull it out open the lock, release the lock automatically after |

| 8 | Rotating the stopper plate | locking external tank |

| 9 | External tank | support within the tank |

| 10 | Within the tank | installation material |

| 11 | Gasket | sealing effect |

| 12 | Cover | puffing, the cover needs to be compressed |

| 13 | Pin | open and close the lid |

| 14 | Pin handle | entangle it with the rod afterburner, and then blasting |

| 15 | Backstop | use for support |

| 16 | Screw | use for locking |

| 17 | Frame buffer | before opening the lid, to move it to the inside |

| 18 | Frame buffer handle | used to move the frame buffer |

| 19 | Heating section | use for heating |

| 20 | Motor | can make the tank rotated |

| 21 | Belt | transportation |

| 22 | Switchback Shun | can make the tank to be rotated and counter-rotated, |

| 23 | Rod Afterburner | before heating, use it to lock the lid 2、after heating, use it to open the lid |

Advantage of cereal puffing machine

- Puffed food can be eaten directly, and it has great taste.

- Air puffing machine can deal with different raw materials such as rice, wheat, corn and nuts, etc.

- The puffing time is short, saving much time.

- The cereal puffing machine is made of stainless steel that complies with the national hygienic standard, widely applying to the peanut candy production line.

- The final puffed food can keep the original nutrient, which is healthy for people.

FAQ

1.What is the temperature of pot before working?

It should preheat to 120 ℃.

2.Can i add some seasoning into raw material before operation?

Yes, of course, you can do it according to your need.

3.What’s the raw material?

They can be soybean, corn, rice, wheat and all kinds of nuts.

Add Comment