The commercial tortilla making machine is a multifunctional machine. This machine can press mature food with water, noodles, and dough into a round or square shape. It can automatically heat the noodles to mature according to the set temperature and time. Moreover, the tortilla maker machine can also make tortillas of different thicknesses and shapes by changing the mold.

Commercial tortilla making machine models

| Model | TZ-200 | TZ-250 | TZ-300 | TZ-350 | TZ-400 | TZ-500 | TZ-600 |

| Tortilla size | 18×0.5mm | 24×0.5mm | 28×0.5mm | 34×0.5mm | 38×0.5mm | 48×5mm | 58×5mm |

| Heating temperature | 0-300℃ | 0-300℃ | 0-300℃ | 0-300℃ | 0-300℃ | 0-300℃ | 0-300℃ |

| Heating time | 0-99s | 0-99s | 0-99s | 0-99s | 0-99s | 0-99s | 0-99s |

| capacity | 1000pcs/h | 800pcs/h | 600pcs/h | 600pcs/h | 500pcs/h | 400pcs/h | 200pcs/h |

| Model size | 20CM | 25CM | 30CM | 35CM | 40CM | 50CM | 60CM |

Tortilla maker machine working principle

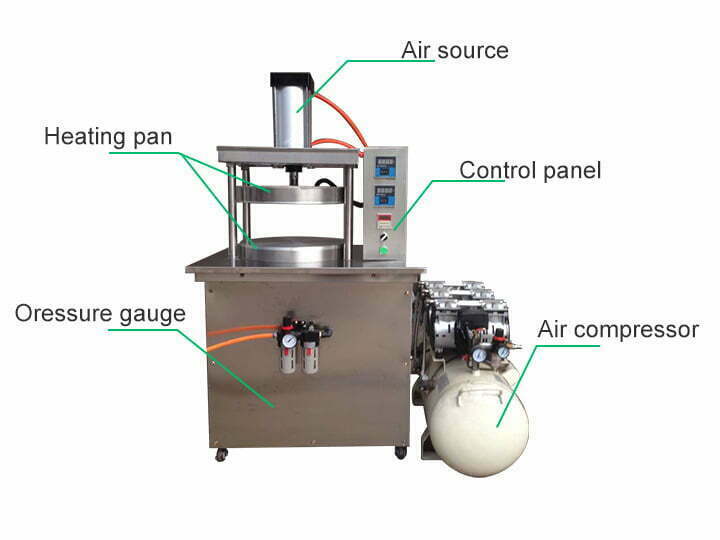

The tortilla maker machine is composed of pneumatic components, electrical components, heating components, and forming molds. Pneumatic components can control the rise and fall of the two cake plates. Electrical components control the operation of each part of the machine.

When using the machine, turn on the power switch to set the heating time and temperature. Then place the dough in the middle of the heating disc. Press the start switch, the upper and lower plates of the heating plate are automatically closed and heated. In the process of closing the upper and lower heating plates, the two heating plates squeeze the dough to form. After heating, the dough is formed and matured. When it reaches the set heating temperature, the machine automatically stops heating and automatically raises the upper mold.

How to control the dough thickness

This automatic tortilla making machine is a pneumatic automatic pressing machine, which needs an air compressor to generate an air source to control the up and down movement of the cake pan. Therefore, the machine can control the thickness of the tortilla by adjusting the amount of air produced by the air compressor.

Automatic tortilla making machine advantages

- The spring roll machine can control the baking by setting the heating time and temperature. After setting the parameters, the machine can realize automatic baking according to this parameter

- The machine can make tortillas of different thickness and shape by changing the mold

- When making doughs, it can add juice or other seasonings to make vegetable tortillas, spring roll wrappers, and other products.

- The temperature control meter of the tortilla making machine can display the temperature of the upper and lower heating plates. When the temperature of the heating plate is lower than the set value, it will automatically heat up and bake. And when the temperature reaches the set temperature, it will automatically stop baking.

- The air volume used by this machine is less than 0.6kg/h, which is very energy-saving.

- Its heating speed is very fast, and a spring roll only needs a few seconds. And by replacing the enlarged mold, it can also produce 2~3 noodles at a time.

- The machine is simple to operate, occupies an area, high production efficiency, and has a wide range of applications. It is suitable for schools, canteens, restaurants, and other institutions.

Instructions for using the tortilla maker machine

- Align the air hole of the air source processor when connecting the air compressor. Pull out the valve that adjusts the air source, rotate the valve to adjust the pressure to 0.5~0.6MPA

- Check the lowering speed of the upper and lower heating plates after starting the machine. Adjusting the switch on the upper part of the cylinder can adjust the speed of mold descent.

- After using the tortilla making machine for a period of time, add a little oil to the cylinder for lubrication.

- After using the machine for a period of time, you can see that there will be water stored in the small tank on the left of the air source treatment. At this time, you should turn off the air source treatment adjustment pressure. Then, pull the small tank to release the water inside.

Add Comment