The ginger powder processing line (ginger powder production line) mainly processes ginger into ginger powder. This ginger powder processing line mainly includes brush cleaning machines, ginger slicers, dryers, flour mills, screening machines, packaging machines, and other machines. The ginger powder processing machine has semi-automatic and fully automatic models. Ginger powder can be used for seasoning, pickling, and soup, and it has a wide range of uses. And it is also very popular in the international market, therefore, the ginger powder processing machine has broad application prospects.

Applications of the ginger powder production line

This small ginger powder processing line can be used to process not only ginger powder but also garlic powder, onion powder, Tumeric powder, etc. Therefore, customers can purchase this line for processing a variety of products.

Usually, the customers who buy our ginger powder processing equipment are engaged in the fruit and vegetable deep processing industry, or engaged in ginger cultivation, spice processing plant, etc.

At present, more than 30 countries and regions have purchased our ginger powder production line, and the most cooperative countries are the USA, Jamaica, Cambodia, Nigeria, India, Indonesia, Thailand, Bangladesh, etc.

ginger powder processing flow chart

Ginger powder production takes ginger as raw material through a series of steps such as peeling, slicing, drying, milling, and packaging. Each step involves a ginger processing machine. Therefore, the ginger powder production line mainly includes a ginger washing and peeling machine, ginger slicer, dryer, sieving machines, and ginger powder packaging machines.

Ginger processing machine introduction

Ginger cleaning and peeling machine

Commercial ginger cleaning and peeling machine is a brush cleaning machine. The machine mainly realizes the peeling function through the friction between the brush and the ginger. While peeling, the machine also connects to a water pipe to spray water. Therefore, after peeling, it can use high-pressure spray water to clean the ginger skin. The commercial ginger cleaning and peeling machine adopt all 304 stainless steel.

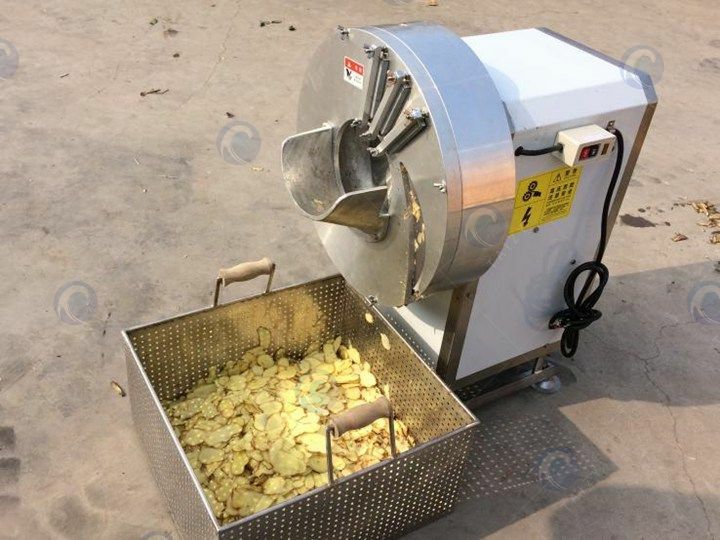

Ginger slicing cutting machine

Ginger slicer is a machine specially used for slicing ginger. Since ginger contains a lot of fibrous tissue, the professional ginger slicer will not have the situation of continuous knives. The ginger slices cut with this ginger slicer have the same thickness and size. Moreover, the machine can also cut ginger into multiple sizes by changing the cutter head. The machine can also cut ginger into shreds and diced shapes.

Ginger slice drying machine

The dryer mainly applies for dehydrating ginger slices. The ginger slice dryer is not only suitable for the ginger powder production line, it is widely used for drying fruits, vegetables, medicinal materials, and other products. And the machine is very intelligent, it uses an intelligent control panel to control the entire drying process. The ginger slice dryer can use electricity, steam, and other heating methods. And it has a lot of models, which can meet the needs of customers with different specifications.

Ginger powder making machine

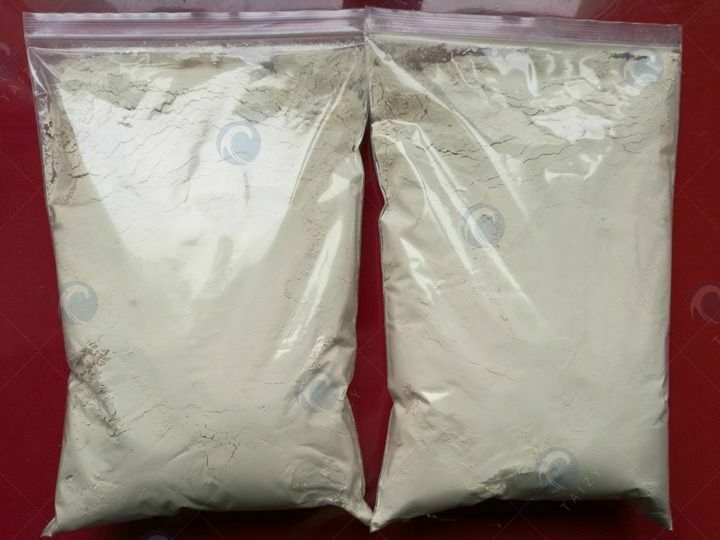

The ginger powder making machine is a machine that grinds the dried ginger slices. The fineness of ginger powder ground by the mill can reach 20~120 mesh. The ginger mill is widely applied for grinding all kinds of grains and medicinal materials. It can realize continuous production with low noise and adjustable feeding speed.

Screening machine

The sieving machine sieving the ground ginger powder. It can customize different screen fineness and sieving levels according to the requirements of screening. It has 3 layers, 4 layers, 5 layers, and many other screen layers. The machine inside is also equipped with a sieving ball to prevent clogging and distribute the ginger powder evenly. The sealing strip ensures that the machine has a good sealing performance and reduces dust emissions.

Ginger powder packaging machine

The ginger powder packaging machine can pack all kinds of powders, such as milk powder, starch, sugar, salt, etc. This automatic ginger powder packaging machine can realize automatic measurement, filling, sealing, cutting, and other tasks. It is controlled by an intelligent control panel, with accurate packaging accuracy and high production efficiency. It can match with the coding machine, air clamping, or inflating device according to requirements.

Ginger powder processing line video

Features of the ginger powder processing machine

- The ginger powder processing machine has a variety of outputs to choose from, it has semi-automatic and fully automatic machines. The basic output of this ginger powder production line is 500kg/h-1t/h. Of course, we can customize the output of this processing line according to the production requirements of our customers. Currently, we have exported ginger powder processing lines with capacities of 1t/h, 2t/h, and 3t/h.

- All ginger powder processing machines adopt food-grade materials and have a stable structure.

- We not only provide a complete ginger powder production line, but we can also match the machine according to the customer’s production process and needs. The ginger powder packaging size, packaging weight, and packaging pattern can be customized based on customer needs.

- The ginger slice dryer has a variety of heating methods, such as electricity, steam, biomass, heat pump, etc.

1T/H ginger powder processing plant configuration form

| Item | Picture | Power | Dimension |

| Bubble washing machine |  | 8.25kw/380v/50hz | 6000x1200x1400mm |

| Hoist conveyor |  | 0.75kw/380v/50hz | 1800*800*1600mm |

| Peeling machine |  | 4.37kw/380v/50hz | 3400*900*1500mm |

| Picking line |  | 0.75kw/380v/50hz | 4000*800*900mm |

| Slicer machine(2 sets) |  | 1.5kw/380v/50hz | 790x660x900mm |

| Hoist conveyor |  | 0.75kw/380v/50hz | 1200*700*1300mm |

| 5 layers drying machine(2 sets) |  | 300kw/380v/50hz | 10000*2200*2000mm |

| Hoist conveyor |  | 0.75kw/380v/50hz | 2000*1200*1400mm |

| Grinding machine |  | 11kw/380v/50hz | 4000*800*2700mm |

| Packaging machine |  | 4kw/380v/50hz | 1300*500*1700mm |

How about the ginger powder manufacturing business?

After grinding ginger into powder, it has a strong taste and obvious fragrance, and ginger powder is good for human health. Take it directly with boiled water, which can increase the body’s heat energy and quickly replenish the body’s heat. Brushing teeth with ginger powder can prevent oral ulcers; ginger powder has a very good effect on removing dandruff and growing hair. In addition, the ginger powder can also remove foot odor and prevent dry feet. It has so many benefits to the human body, and the ginger powder manufacturing business has broad prospects.

Ginger powder production in Nigeria

Last year, one of our Nigerian customers bought a complete ginger powder processing machine to produce ginger powder. Now it has been put into the production of ginger powder in Nigeria. Nigeria is the main ginger producer on the African continent. Nigeria produces about 160,000 tons of ginger each year, most of which are exported overseas.

Dehydrated ginger flakes and ginger powder are the main export products, and their main markets are Europe, America, and Canada. The huge export demand for ginger powder has increased the ginger powder production business. The Nigerian customer purchased a complete set of ginger powder production equipment. The local voltage is 380v 50hz 3-phase electricity, so we modified the voltage of the machine for this customer. And all ginger powder processing machines adopt 304 stainless steel, which has a stable structure.

Add Comment