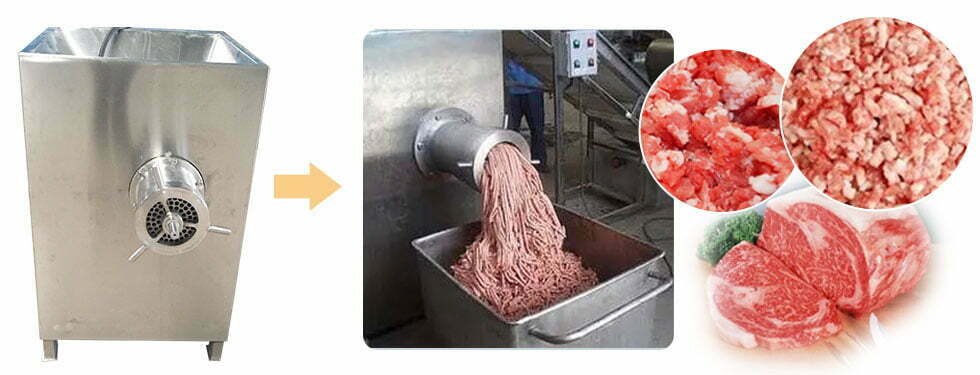

The industrial frozen meat grinder machine is one of the indispensable auxiliary equipment in meat processing. It has high versatility and wide application in the meat production industry.

The equipment pushes the raw meat in the feed box forward to the pre-cutting section under the thrusting of the screw rod. It makes the orifice plate and the reamer run relative to each other through the rotary extrusion.

Therefore, it cuts the raw meat into particle shape and ensures the evenness of the meat filling. Different combinations of orifice plates can be used to achieve the production requirements on meat filling granules of different sizes.

Commercial frozen meat grinder machine application

The commercial frozen meat grinder machine is widely used in restaurants, dining halls of enterprises, and meat roasting and cured bacon factories for making minced meat. The industrial frozen meat grinder applies for processing all kinds of frozen meat, fresh meat, chicken with bone, duck with bone, mutton, chicken and beef with skin, fish, and so on.

Industrial meat grinder machine classification

According to the degree of meat processing, it includes a fresh meat grinder machine and a frozen meat grinder machine. In the food processing industry, single-stage meat grinders are applied more often. By replacing different orifice plates sizes, it can achieve the purpose of adjustable thickness. Meanwhile, it avoids the impact of rising in temperature of raw material thus affecting the meat quality.

Working principle of meat grinder

The meat grinder is the most commonly used machine for meat processing. It mainly reaches its grinding and mincing effect under the interaction of stainless steel grid plate and cross-cutting knife. During this process, the meat will be chopped, minced, and then be formed into meat strips for filling making.

The meat grinder machine mainly composes of a feeding unit, meat mincing chamber, cutting unit, and transmission units.

During processing, under the shearing action generated by the rotating cutting blade and the eyelet blade on the orifice plate, the raw meat is minced and ground. Under the action of the screw, the minced meat is extruded and discharge out of the machine through the outlet continuously.

Performance of frozen meat grinding machine

A meat grinding machine is a meat processing equipment with a high degree of versatility and a wide application range in the meat production industry.The industrial frozen meat grinding machine pushes the raw material forward under the action of the screw to push the raw meat in the hopper box forward to the pre-cutting unit.

Characteristics of frozen meat grinder machine

- The ideal meat filling can be obtained by different combinations of orifice plates.

- Mincing frozen meat thoroughly.

- Positive and negative rotating prevent the mincer cutters from material blocking;

- The meat mincing equipment is characterized by versatility, wide application, and high output;

- It has the function of mincing and grinding frozen meat, with time, labor saved, freshness and quality guaranteed;

- Due to its short cutting time and the low operating temperature, the freshness is maintained with a shelf life of the minced ground meat prolonged;

- Multiple orifice plate combinations can meet the requirements of processing meat products of a wide variety.

Add Comment