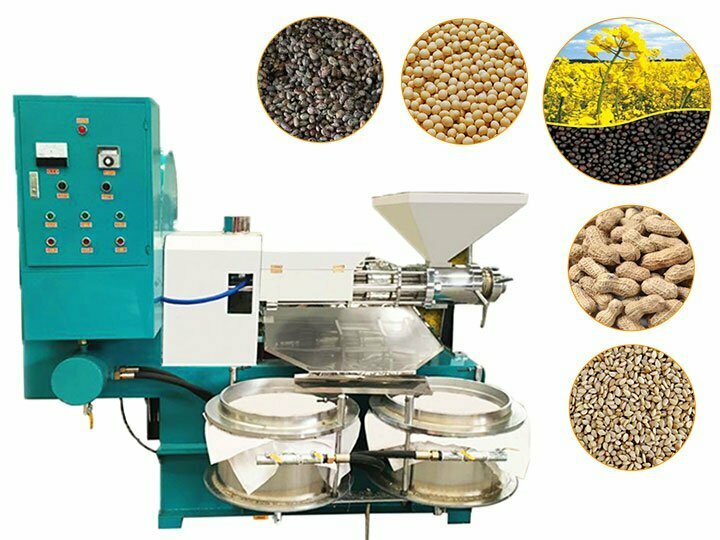

A screw oil making machine is a machine that squeezes the oil components contained in the oil crops. It is a stainless steel oil machine with one screw. The raw material can be soybeans, peanuts, cotton seeds, rapeseed, olives, sunflower seeds, etc. Before the oil press machine works, you should preheat the machine for about 20 minutes, and the temperature of the pressed peanuts is about 180℃. The thickness of the oil residue with a round shape can be adjusted. There are two pressing ways including hot pressing and cold pressing. Hot pressing means that the operator roasts the raw material in a pan before pressing the oil. (High oil yield). Cold pressing means that the operator places the raw material into the oil pressing machine directly.

The oil making machine is equipped with two oil filters to simply filter impurities and fried residues, so the pressed oil can be eaten directly.

Oil pressing rate towards different raw materials of oil extraction machine

| Raw material | Oil pressing rate(%) | The thickness of oil residue | The residual oil rate of oil residue |

| Sesame | 48-55 | 1.0-1.5 | ≤7 |

| Peanut | 40-43 | 0.8-2.0 | ≤8 |

| Rapeseed | 36-42 | 1.0-1.5 | ≤8 |

| Sunflower seed | 50-55 | 1.2-1.5 | ≤8 |

| Beans | 13-18 | 0.8-1.5 | ≤7 |

| Tea seed | 26-38 | 1.0-1.5 | ≤7 |

| Walnut kernels | 60-70 | 1.0-1.5 | ≤7 |

| Specification | Model | Motor power | Capacity | Dimension(mm) | Weight(kg) | Remark |

| Two-phase electric | 60 | 2.2kw | 30kg | 1200x 800×1160 | 230 | Including oil pressing machine, oil filter, fried pan

Voltage:220v |

| 70 | 3kw | 60kg | 1400x 950×1250 | 280 | ||

| 75 | 4kw | 75kg | 1400x 940x 1300 | 290 | ||

| Three-phase electric | 80 | 5.5kw | 100kg | 1650x1500x 1600 | 565 | Including oil pressing machine, oil filter, fried pan

Voltage:380v |

| 100 | 7.5kw | 200kg | 2000x1500x 1720 | 760 | ||

| 125 | 11kw | 300kg | 2100x1500x 1750 | 920 | ||

| 130 | 18.5kw | 400kg | 1850x1700x 1760 | 1100 | ||

| 150 | 22kw | 450kg | 2600x2100x 1780 | 1200 |

The structure of the oil extractor

The oil extraction machine mainly consists of five parts as electric control part, the heating and pressing part, the adjusting part, the transmission part, and the vacuum filter oi part.

- The electric control part includes an air switch, AC contactor, temperature, control instrument, and circuit automatic protection device.

- The heating and pressing part is composed of a heater, a pressing screw, and the body.

- The oil extraction machine’s transmission part is composed of the main shaft and the gearbox, the pulley, the motor wheel, etc.

- The speed adjusting part is composed of an adjusting screw, a regulating nut, a handle, a locking nut, etc.

- Its vacuum filter oil part is composed of a vacuum pump. oil filter tube and other assembly components.

Advantages of oil making machine

- High oil press rate.

- The final oil is very clean without any residue. Two oil filters can enable the cleanness of the final oil.

- A special screw structure is able to press oil with high efficiency.

- The screw oil making machine is suitable for different raw materials such as soybeans, peanuts, cotton seeds, rapeseed, olives, and sunflower seeds.

- This large type of oil press machine is better than the hydraulic oil press in mass oil production.

How to install an oil making machine?

- The oil pressing machine should be installed in enough space.

- Place the machine and oil filter horizontally.

- After installation, the 0.5-1m ground wire should be connected to the machine, and the gap between is 3-5m.

How to operate an oil-making machine? (1)

1. Carefully read the manual before working.

2. Before starting the oil-making machine, a comprehensive inspection should be conducted such as not loose fasteners, flexible rotation of the handle, and rotating the pulley by hand. All working parts should be normal, and then add lubricating oil to the gearbox.

3. Operator loosens the lock nut, and counterclockwise rotates the adjustment screw, enabling the conical surface of the screw and oil residue shall be closed. Then you can clockwise rotate the adjustment screw to 2-3mm and then rotates the locking nut so as to start the oil-making machinery.

How to operate the screw oil extraction machine? (2)

4. Open the door of the electric box. switch on the air switch (placed in a reasonable position) in the box, that is, the power of the whole oil extractor machine is switched on.

5. Adjust the temperature of the oil extractor to 150200 ℃(it is different according to different raw materials). Then open the total heating switch to heat the machine, and the green light of the temperature controller is on at this time. The red light is on when the temperature of the machine reaches the required one. The machine temperature is set automatically and kept within a set range.

6. It is necessary to keep the feeding evenly. The thickness of the oil residue is normally controlled at 0.5-2mm. The oil residue should be smooth, ensuring that the low-pressure section basically is no slag. A small amount of oil slag can exit in the high-pressure section, but the proportion of slag in the oil is not more than 10%. The temperature inside the pressing part can reach 105200℃, and the green smoke at the oil residue outlet should be discharged through the shield. The oil residue should be spread out in time. When the working time is long and the machine temperature is too high, the fan should be used to cool down(the heater can stop working when the screw oil press works continuously).

How to operate a screw oil press machine? (3)

7. Press the forward button and the main unit starts to run. The rotation direction of the screw shaft should be counterclockwise.

8. When the squeezed oil flows on the filter oil, you should first check whether the vacuum pump motor rotates correctly. The vacuum pump starts to run when pressing the vacuum pump button. The air in the filter oil tank is drawn out, and negative pressure is formed in the barrel. The oil naturally flows into the filter drum, and the oil residue is isolated on the filter cloth. After the pressing is completed, the vacuum pump is stopped. the venting valve of the filter oil is opened, and the dry slag is formed on the filter cloth. The dry is removed by using a scraper to scrape off (can not scrape off if the negative pressure is formed in the barrel).

9. Prohibitfeeding before stopping the machine, and adjust the gap of oil residue. After the waste material is drained, the oil residue is no longer discharged. The adjusting screw is screwed out 1-3 rounds smoothly. Finally cut off the power.

The FAQ of essential oil making machine

What's the raw material?

The raw material can be soybeans, peanut, cotton seeds, rapeseed, olives, sunflower seeds

Can hot pressing press more oil?

Yes, of course, compared with cold pressing, hot pressing can get more oil.

Does the finally contain any residues?

No, the oil pressing machinery is equipped with two oil filters that can filter the impurities in the oil.