The hydraulic oil press machine is used to extract oil from peanut, soybeans, sesame, sunflower seeds, walnut, pine nut, almond, etc, and boasts a high oil yield. With easy operation and various models, these oil press machines have been exported to many countries, greatly improving working efficiency compared with manual operating. This small hydraulic oil press machine presses little materials per time(2-7kg) and the pressing time is short(8-12min) so it’s popular in large and medium cities.

In addition, different models have different pressing times (8-12min). It has the characteristic of a simple process and easy maintenance. This machine can make pure oil without seepage. The hydraulic oil press machine is mainly composed of a barrel, cylinder, handle, hydraulic handle, pressure relief valve, grease nipple, etc. The hydraulic oil press machine is made of high-quality metal materials to improve machine performance and ensure component service life.

Hydraulic oil press equipment working video

Technical parameter of hydraulic oil press machine

| Model | 6YZ-150 | 6YZ-180 | 6YZ-230 | 6YZ-260 | 6YZ-320 |

| Barrel

Diameter(mm) | Ф150 | Ф185 | Ф230 | Ф260 | Ф320 |

| Loading weight(kg) | 2 | 4 | 8 | 11 | 15 |

| Pressing

time (min ) | 8 | 8 | 10 | 12 | 12 |

| Nominal

Pressure | 55 | 55 | 55 | 55 | 50 |

| Working

pressure (t) | 65 | 100 | 175 | 230 | 265 |

| Motor

power(kW) | 0.75 | 1.5 | 1.5 | 1.5 | 2.2 |

| Heating.

power(kw) | 0.6 | 0.8 | 0.9 | 1.0 | 1.2 |

| Weight

(kg) . | 250 | 750 | 1050 | 1400 | 2000 |

| Dimension

(mm) | 400*500*850 | 500*600*1100 | 600*750*1350 | 650*900*1450 | 800*950*1700 |

Vulnerable parts of hydraulic oil press machine

| No. | Name | Specification

| Quantity | Part |

| 1 | Oil seal | 45x25x10 | 1 | Driving shaft |

| 2 | Seal ring | YxD220x200x 18 | 2 | Inside the cylinder |

| 3

| Plunger | Ф13 | 2 | Pump |

| Ф16 | 1 | |||

| 4 | Bearing | 7205 | 1 | Pump |

| 5 | Bearing | 6205 | 2 | Pump |

| 6 | Belt | A1200-1250 | 3 | Motor |

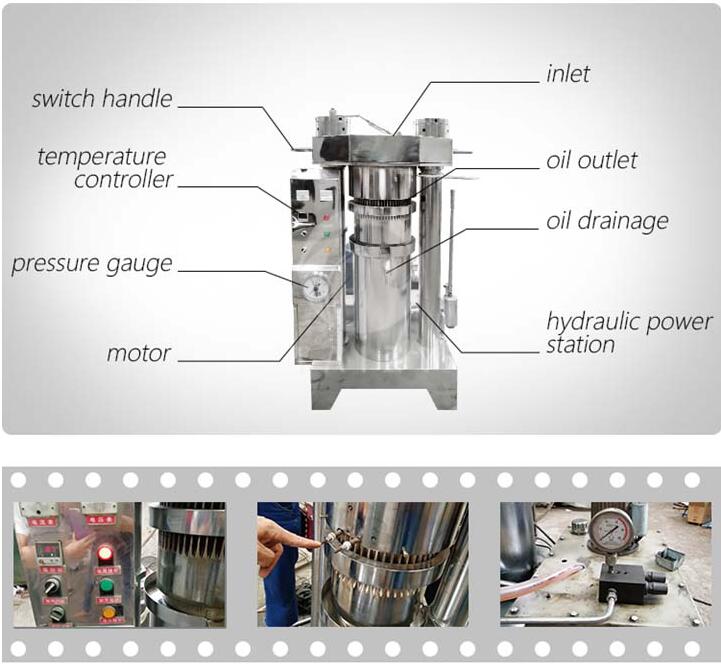

Structure of commercial hydraulic oil press machine

This commercial oil press machine consists of three parts, that is, driving part, the electrical control, and the main body.

The main body is composed of the base plate, vertical shaft, top plate, pressing chamber, oil pan, screw nut, etc. The cylinder can push the raw material that lies in the screw chamber to press. Finally, the oil flows out from the chamber and enters the container.

The driving hydraulic part is the main power driving source with an advanced hydraulic pump. It consists of a driving shaft, worm gear, worm, gear pump, high-pressure pump, overflow valve, hand control valve, cylinder assembly, conduit couple, etc.

The electrical control part is composed of an engineer, voltmeter, temperature control, an adjusting table, pressure gauge, power insurance, etc.

The advantage of the hydraulic oil extraction machine

- Hydraulic oil press machine equips with a faster-pressing speed, and it can press oil in a short time.

- The machine is able to bear high temperatures without any cooling device even if the oil temperature is above 65C.

- Lownoise, lightweight, small volume, low power consumption(can save at least 30% power compared with double plunger pump), and energy-saving.

- Due to the hydraulic device(high pressure), automatic control system, and preheating temperature control, the sunflower oil pressing machine has a high oil yield with high quality.

- Wide application

- Hotpress material: Sesame, flax, peanut, rapeseed, wheat germ, corn germ, etc.,

- Cold press material: Walnut kernels, pine nuts, almonds, olives, macadamia nuts, camellia seeds, etc.,

- Condiments: Pepper, mustard seed, etc.,

6. Good oil quality

Pure physical pressing with high oil yield. It will not produce temperature during cold pressing, therefore the organic components of the oil will not be destroyed. It has the characteristics of good oil quality, low impurity, and a wide application range.

7. Easy to operate and high efficiency: Mechatronics design with a w failure rate. The high degree of automation needs 8-10 minutes for one-time pressing. It has a beautiful appearance and is easy to operate. One can operate 3-4 sets.

Use of the hydraulic oil press machine

- Turn on the power and check that the indicator is working properly. When using the machine for the first time, the pump station lever is placed in a horizontal position. Continuously turn on and turn off the machine ten times to evacuate the gas in the pump station. Turn off the machine and turn on the thermostat switch.

- Put the level to the vertical position, and turn on the power. When the piston in the barrel is raised until the platen can be taken out, turned off the switch immediately.

Note: Do not raise the piston too high. Remove the pressure plate and do not move any other parts in the barrel.

- Open the top cover, put a cotton pad, then pour the fried material(or not fried material)into the barrel. Put another cotton pad and the pressure plate, then close the top cover. Finally, put the level to the vertical position, start the switch, and start the oil press.

- Under normal circumstances, the machine will automatically stop when gauge pressure reaches 55 ( 50 ) MPa, and it will automatically work when gauge pressure reaches 40MPa. Repeat 2-3 times. Turn off the switch. Put the level to the horizontal position for about 20 seconds and then re-position it to the vertical position. Open the top cover and the main switch. Take out the oil cake and put the level in the horizontal position. The machine can continue work when the piston declines to the bottom.

Note: The hose on the back of the machine is connected to the back pipe and pump station on the back of the main unit, which is to prevent the hydraulic oil from flowing out when the piston is raised too high.

The preoccupation with oil press machine

- Voltage is 220v or 380v.

- Users should have grounding protection measures.

- The hydraulic pressure is 55 MPa.

- The oilseed with smoke will trigger the gas explosion.

- If the sump gets blocked, the customer should use a thin blade or needle to clean it.

- The hydraulic oil needs to be changed once a year, and the hydraulic oil press machine should be off if you do not use it for a long time.

Hydraulic oil press machine exported to Austria case

We delivered 4 sets of hydraulic oil press machines to Austria last week, and he bought the model 6YZ-180. The following are the packing details.

The raw material for this Australian customer is avocado. After understanding, we recommend he use this hydraulic oil press. The hydraulic oil press can squeeze sesame, avocado, olives, and other raw materials. Moreover, the oil and fat squeezed by the oil press are purer. Therefore, it generally does not need to use an oil filter to filter the oil. After the customer bought the oil press, we changed the voltage of the machine according to the local voltage. Moreover, we also provided him with transportation services.

FAQ of oil press machine

Is this oil press machine equipped with an oil filter?

No, you need to buy an extra oil filter.

How is the pressing rate?

The pressing rate is very high thanks to the hydraulic device.

Do I need to frequently change the hydraulic oil?

No, you can change it once a year.

What is the raw material?

They can be peanut, soybeans, sesame, sunflower seeds, walnut, pine nut, almond, etc.