The industrial food sterilizer machine is used in the food processing industry to sterilize processed food. After using the food sterilizer to sterilize, it can ensure the stability of the food and help extend the shelf life of the food. According to different sterilization methods, Food sterilization machine has various sterilization machines such as autoclave sterilization machine, water bath sterilization machine, pasteurization machine and so on. Industrial food sterilization machine is widely used in the sterilization of retort pouch and canning food.

Types of Food Sterilizer machine

According to different sterilization methods, food sterilization machines mainly include autoclave sterilization machines, water bath sterilization machines, pasteurization machines, and other machines. They are suitable for the sterilization of canned and bagged food.

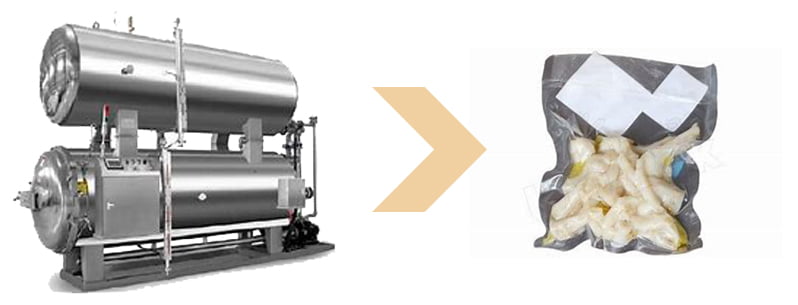

High pressure autoclave sterilization machine

The high-temperature autoclave sterilizer machine widely applies for the sterilization of canned or bagged food such as meat, beans, mushrooms, and fish. According to the different sterilization methods, the machine can choose different sterilization methods such as steam type, water bath type, spray type, and so on.

The characteristics of autoclave sterilization machine

- Uniform thermal distribution, no dead angle, the circulating water in the sterilization tank flows uniformly with the flowing direction switched constantly up, down, left, right, thus ensuring any point of the heat distribution is uniform inside the vessel from the period of heating, heat preservation to cooling.

- High temperature short time sterilization is materialized by adopting the double vessel hot water circulation as the means of sterilization. The water in the hot water tank is first heated to the temperature required for sterilization (except multi-stage sterilization), thus shorten the sterilization time, and improve the work efficiency.

- Save energy. The working medium water used in the sterilization process in the sterilization vessel can be recycled for energy saving, shortening time, and reducing manpower and waste, as a means of reducing production costs.

- Automatic control system. The whole sterilization process can be controlled by the computer, therefore the operation can be completed automatically.

- Bactericidal kettle adopts temperature simulating control system, which can set multi-stage heating mechanism prior to starting.

Parameter of retort pouch food sterilizer machine

| diameter(mm ) | length(mm) | volume(m³) | thickness

(mm) |

Water pump | ||

| type | number | |||||

| Sterilizer pot | Thermo kettle | |||||

| φ500 | 800 | 0.20 | 4 | 4 | DN20 | 2 |

| φ600 | 1000 | 0.35 | 4 | 4 | DN32 | 2 |

| φ700 | 1200 | 0.57 | 4 | 4 | DN40 | 2 |

| 1500 | 0.69 | 4 | 4 | DN40 | 2 | |

| 1800 | 0.80 | 4 | 4 | DN40 | 2 | |

| φ900 | 1800 | 1.37 | 4 | 4 | DN65 | 2 |

| φ1000 | 2200 | 2.03 | 4 | 4 | DN65 | 2 |

| 2400 | 2.18 | 4 | 4 | DN80 | 2 | |

| 2600 | 2.34 | 4 | 4 | DN80 | 2 | |

| 3000 | 2.66 | 4 | 4 | DN80 | 2 | |

| φ1200 | 2700 | 3.56 | 5 | 5 | DN80 | 2 |

| 3000 | 3.90 | 5 | 5 | DN80 | 2 | |

| 3600 | 4.58 | 5 | 5 | DN100 | 2 | |

| 4000 | 5.03 | 5 | 5 | DN100 | 2 | |

| φ1300 | 3000 | 4.62 | 5 | 5 | DN100 | 2 |

| 4000 | 5.95 | 5 | 5 | DN100 | 2 | |

| 5000 | 7.27 | 5 | 5 | DN100 | 2 | |

| φ1500 | 4000 | 8.04 | 5 | 5 | DN125 | 2 |

| 5000 | 9.80 | 5 | 5 | DN125 | 2 | |

| 6000 | 11.58 | 5 | 5 | DN125 | 2 | |

| Design pressure | 0.35 Mpa |

| Maximum pressure | 0.30 Mpa |

| Material | SUS304 |

| Design temperature | 147℃ |

Water bath sterilizer

The water bath sterilizer is widely used in canned food factories. This machine is ideal equipment for pasteurizing canned fruit pulp. The high temperature and high-pressure water bath sterilization machine can achieve continuous sterilization, and the temperature can be adjusted by itself. When sterilizing, it makes the bottle body of the food can be soaked in heat-conducting water. Therefore, the machine makes the sterilization more thorough.

Food pasteurizer machine

Pasteurizers have a very wide range of applications. It is widely used to sterilize dairy products, soy products, canned food, bagged food, and other foods. The pasteurizer can also form a sterilization line with equipment such as a cooler, a vibration drainer, an air-drying dewatering machine, and a conveyor. The assembly line can be designed and produced according to different products, different output, and different process requirements to meet the needs of customers at different levels.

Add Comment