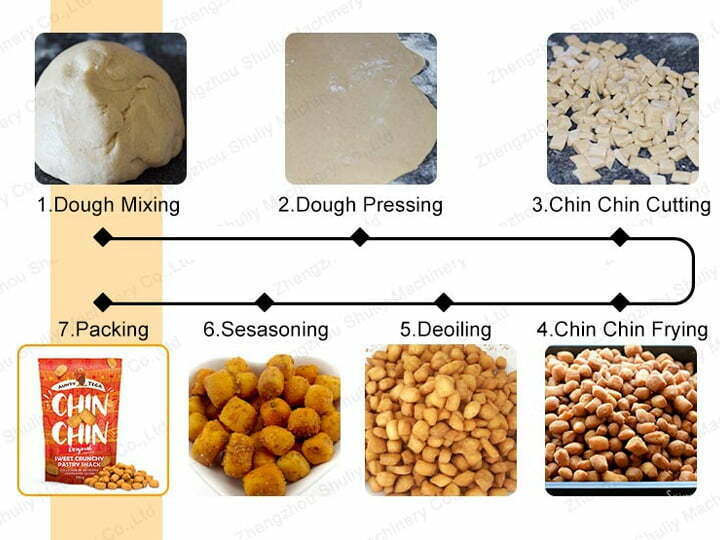

The chin chin production line is used to make the fried pasta snack chin chin, which is very popular in West Africa. It is especially popular in Nigeria and Ghana. The turnkey project of the entire chin chin production line includes a dough mixing machine, noodle pressing machine, chin chin cutter, fryer, de-oiling machine, and packaging machine. Through these automated chin chin processing machines, factories can realize automated commercial production.

Why is the chin chin production business so popular?

Chin chin is a very popular fried pasta snack in West African countries. In these West African countries, chin chin is a snack often eaten at parties and leisure. Because it is easy to make, it can be eaten anytime and anywhere, and it is very delicious. Therefore, the production and business of chin chin have gradually expanded from West African countries to the United Kingdom, the United States, the Philippines, Canada, and other countries and regions.

How to make chin chin commercially?

Chin chin is a fried noodle snack. Its raw material is flour. The flour is made into dough, and then the dough is cut into strips with a knife. Then put the long-shaped dough into the deep fryer and fry it into shape.

Chin chin production line configuration

Commercial chin chin production usually requires the use of chin chin machines. Many factories purchase a complete set of chin chin production lines to produce chin chin. The chin chin production line equips with a dough mixer, noodle pressing machine, chin chin cutter, chin chin fryer, degreasing machine, and packaging machine.

Introduction of the chin chin processing machine

Kneading machine

In the commercial chin chin production line, generally use a batch kneading machine. It can mix a certain amount of flour and water at one time to obtain a mixed dough. The dough mixer uses the rotation of the mixer to mix the flour and water until a large mixed dough is obtained. The whole machine adopts food-grade stainless steel. The batch mixing output is 25kg, 50kg, 100kg, etc.

Noodle pressing machine

The noodle pressing machine presses the dough repeatedly through the processes of conveying, kneading, pressing, and folding the dough. It replaces the complicated process of traditional manual dough kneading. It reduces labor intensity to a large extent and improves work efficiency. In addition, the dough sheet after repeated pressing is smoother, more delicate, and refreshing.

Electric chin chin cutter

The electric chin chin cutter is an important machine in the chin chin production line. The machine mainly cuts the whole piece of dough into regular shaped strips. The machine can also change different cutter molds to cut dough into different shapes. The chin chin cutting machine has a small and continuous automatic model, and customers can choose the right machine according to the output.

Chin chin fryer

Chin chin Fryer is used for frying chin chin so that chin chin will mature and shape. There are many choices of chin chin fryer, such as box fryer, circular fryer, and continuous mesh belt fryer. Their degree of automation is different. Semi-automatic chin chin production line can choose box type and round fryer. The continuous mesh belt fryer is usually used in large-scale chin chin processing plants.

De-oiling machine

In order to prevent a large amount of fat attached to the chin chin after frying, which affects the taste of the chin chin. It needs a degreasing machine to remove the excess oil on the chin chin. The deoiling machine usually uses the centrifugal principle to deoil. The deoiling time can be timed, and an alarm device can be added to remind.

Chin chin packaging machine

The chin chin packaging machine is usually a granule packaging machine. The chin chin packaging machine can realize the steps of automatic measurement, filling, bag filling, and sealing. And the weight of each bag can be controlled through the intelligent control panel.

Taizy chin chin production line features

1. The chin chin production line has two specifications, semi-automatic and fully automatic, to meet the needs of large, medium, and small chin chin manufacturers.

2. The cutting size of the chin chin cutter can be exchanged by changing the knife.

3. All the chin chin processing machines adopt food-grade stainless steel, which meets the requirements of food safety and sanitation.

4. The machine has a reasonable design, stable structure, and easy operation.

5. The frying machine can choose electricity, gas, and other heating methods.

6. The size of the chin chin packaging machine can be customized.

Is the chin chin production business profitable?

Taizy chin chin production machine manufacturers have sold many chin chin processing machines to Nigeria, Canada, the United Kingdom, and other places. As far as we know, many chin chin producers in other countries are mainly sold in Nigeria. In other regions, there is still a lot of room for chin chin production business. The price of Taize’s chin chin production machines is very competitive. It only takes a short period of time to recover the investment funds of the machine. Therefore, the chin chin production business is profitable.

How and how much can l get the cutter machine?

Nice to receive your inquiry, I will send you the details via email soon

Dear sir

Can you send me a quotation for this machine?

Best regards

Nice to receive your inquiry, I will send you the details via email soon