A mango drying machine (fruit dryer) is a machine designed for removing moisture from various fruits such as mangoes. Through the mango dryer, it can reduce the moisture contained in the mango to a specific value. Dried mango is a kind of fruit with very high nutritional value. It is a special snack in Thailand, the Philippines, and other places. The industry mango dehydrator equipment can quickly dry large quantities of mangoes. And it can realize continuous drying. Therefore, the commercial mango drying machine has high economic benefits for many food processors.

Commercial fruit dryer machine application

The fruit drying machine widely applies for drying various fruits with high water content. Such as drying pineapple, lychee, banana, kiwi, star anise, and other fruits. In addition, the dryer is also suitable for drying other food materials, herbs, spices, and other materials. The machine can set multi-stages temperatures and times. Therefore, it can control the final raw material moisture content.

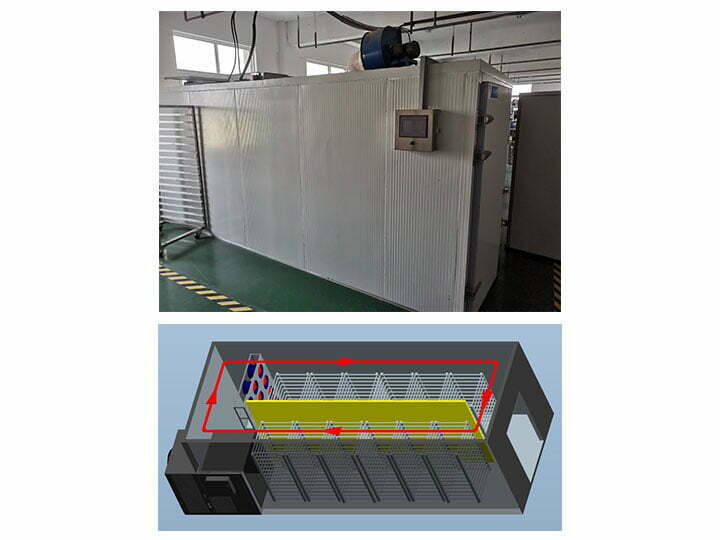

Industrial mango drying machine drying principle

The mango drying equipment mainly uses circulating hot air to dry mango and other fruits. The machine mainly generates hot air from heat sources such as electricity, gas, biomass particles, and air energy heat pumps. The hot air circulates in the entire drying box through a circulating fan. Therefore, the circulating hot air can fully and evenly contact the mangoes. During the drying process, the circulating hot air will take away the moisture in the mango and form moisture. The moisture exhaust fan of the mango dryer will exhaust the moisture. Therefore, the automated mango dryer can realize the function of drying mangoes.

Commercial mango dehydrator machine characteristics

- The entire drying process is carried out in a closed space with high thermal efficiency and can effectively save energy.

- The use of heat sources such as biomass particles and air energy heat pumps can effectively save energy consumption and reduce drying costs.

- It can adjust the drying time and temperature according to the drying process and the material moisture content. And it can automatically control the humidity, then it will stop automatically when it reaches the humidity required for drying.

- The circulating hot air continuously circulates in the drying box, so that the temperature difference in the mango drying box is small, ensuring uniform drying.

- It has a good drying effect, which can ensure that the dried mango has good color and less nutrient loss.

- The automatic mango drying machine makes up for the shortcomings of natural drying that is restricted by the weather. And the use of mechanized drying can carry out mass continuous production and realize automatic management.

Drying mango process with the mango drying machine

It has mainly undergone the steps of raw material selection, washing, peeling, slicing, color protection, drying, softening, and packaging for drying mango.

- Raw material section

It should select the ripe fresh mangoes with thick flesh as the raw material for making dried mango. The mangoes’ maturity should be8~9. Too low or too high will affect the drying effect of mangoes.

- Cleaning mango

Put the selected mangoes into the washing machine for automatic washing. And after the washing machine, it can equip with a grading machine and selection table to classify the mangoes and select the unqualified mangoes. After cleaning and draining the mango, it can carry out the next step of peeling and slicing.

- Peeling and slicing

Mangoes have a larger core, and the mango skin contains more tannins. The mango skin must be removed cleanly. If it is not removed, it will easily cause browning during the drying process and affect the quality of the dried product. The peeled fruit needs to be cut into 8~10mm slices with a sharp blade.

- Color protection

The cut mango slices should immediately undergo the color protection procedure. This step can use sulfur fumigation or sulfur leaching method. This step can achieve the purpose of color protection and taste preservation.

- Drying mangoes

Place the color-protected mango slices evenly on the drying tray. Then put the drying truck with the tray into the mango drying machine. The drying of mangoes has roughly gone through three stages. It can set the required drying time, temperature, and humidity for each stage on the PLC display screen. After the machine runs for the set time, it can indicate the end of drying.

- Soften

Use a mango dryer to reach the required drying moisture (usually 15% to 18%), then take out the mango and place it in a closed container to soften it. The softening time is generally 2 to 3 days. The purpose of this step is to keep the moisture content of the various parts of the mango balanced so that the mango texture becomes soft and convenient for packaging.

- Dried mango packaging

After completing the above steps, it can carry out the final packaging. The choice of packaging machine can be based on the packaging style, budget, and other factors selected for the appropriate machine.

Très intéressant, pourrai je avoir les différentes capacités et le prix en $ stp.

Ravi de recevoir votre demande, je vous enverrai bientôt les détails par e-mail