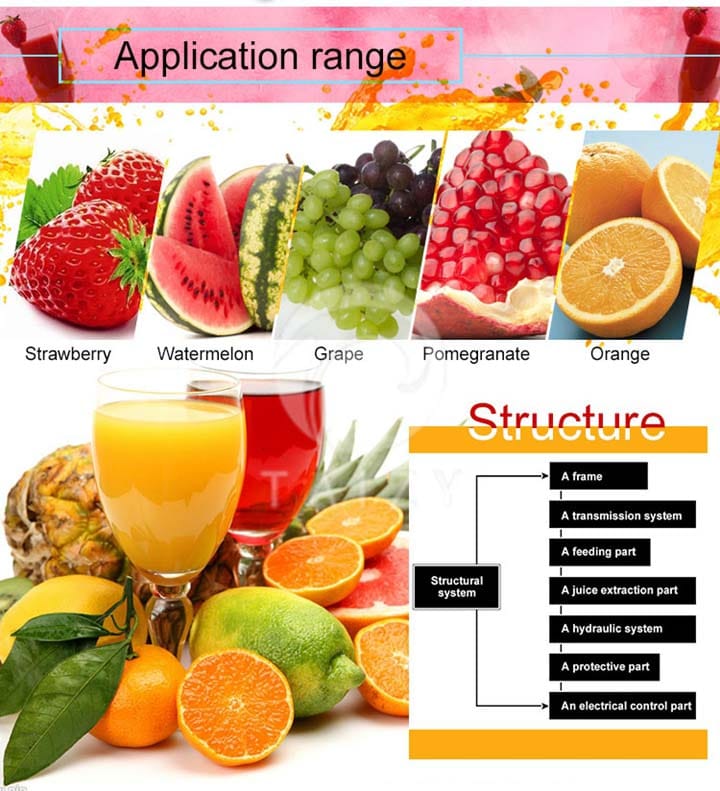

The industrial fruit juicer machine is a multi-functional fruit juice extractor machine. It applies to making various kinds of vegetable and fruit juice. The whole machine adopts stainless steel and consists of a frame, transmission system, inlet, juice pressing part, hydraulic system, protective cover, and motor. People mainly use it to extract juice from fruit such as apples, pears, lemons, etc., and other raw materials. Different models bear different capacities, that is, from 200kg/h-10t/h, and you can choose one in accordance with your need. Today I will introduce you to two types of machines including a single screw juicer machine and a double screw juicer machine.

Industrial fruit juice extractor machine introduction

The pomegranate juice extractor machine is used for solid-liquid separation operations for fibrous materials or viscous materials. Such as fermented grape skin residue, ginger, spinach, rubber, Chinese herbal medicine, winter jujube, and other fruit and vegetables. It is also used for continuous juice extraction of sea buckthorn with small twigs. The mesh hole is specially made according to the size of the sea buckthorn. It is also used in environmental protection industries, such as press dewatering of market waste and kitchen waste.

Type one: single screw juicer machine

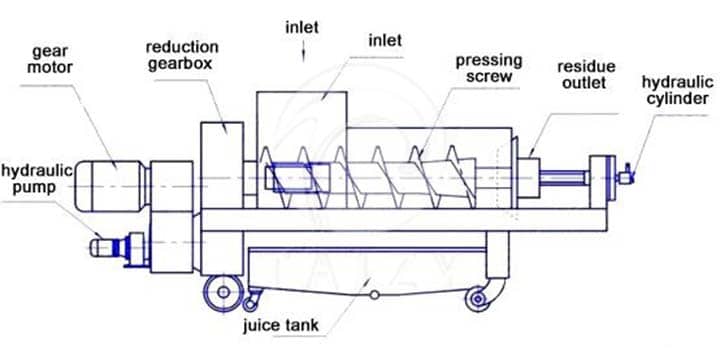

The single screw juice squeezer adopts a gear motor, hydraulic pump, reduction gearbox, juice tank, inlet, pressing screw, residue outlet, and hydraulic cylinder. Its capacity is 3t/h, 20t/h, and 40t/h.

As for a single screw fruit juicer machine, the spiral and spindle rotate in the same direction. It is suitable for pressing raw materials with a relatively smooth surface and containing fewer plant fibers, such as grapes, berries, cabbage, melon, aloe, Chinese medicine residue, and other fruits and vegetables.

| Model | DYZJ-5 | DYZJ-10 | DYZJ-20 | DYZJ-30 | DYZJ-40 | DYZJ-50 |

| Capacity | 2-5t/h | 4-10t/h | 10-20t/h | 15-30t/h | 20-40t/h | 25-50t/h |

| Power | 11KW | 22KW | 30KW | 37KW | 45KW | 55KW |

| Diameter of screw | 420mm | 500mm | 620mm | 700mm | 780mm | 860mm |

| Rotation speed o screw | 5-12r/min | 5-13r/min | 5-14r/min | 5-15r/min | 5-16r/min | 5-17r/min |

| Hydraulic power | 1.5KW | 1.5KW | 1.5KW | 2.2KW | 2.2KW | 2.2KW |

| Dimension (mm) | 4550X960X1500 | 5050X1000X1500 | 560X1100X1800 | 6500X1200X2000 | 7200X1300X2200 | 8300X1500X2550 |

| Weight | 2700kg | 3500kg | 4500kg | 6000kg | 8500kg | 12000kg |

Type two: twin screw fruit juicer machine

As for the double screw pressing machine, the twin screw apple juice extractor machine is opposite the conveying screw. It is suitable for raw materials that contain more plant fibers, such as common grapes, dregs, sugar cane, pulp, vegetables, plant leaves, etc.

Working principle and structure of fruit juicer machine

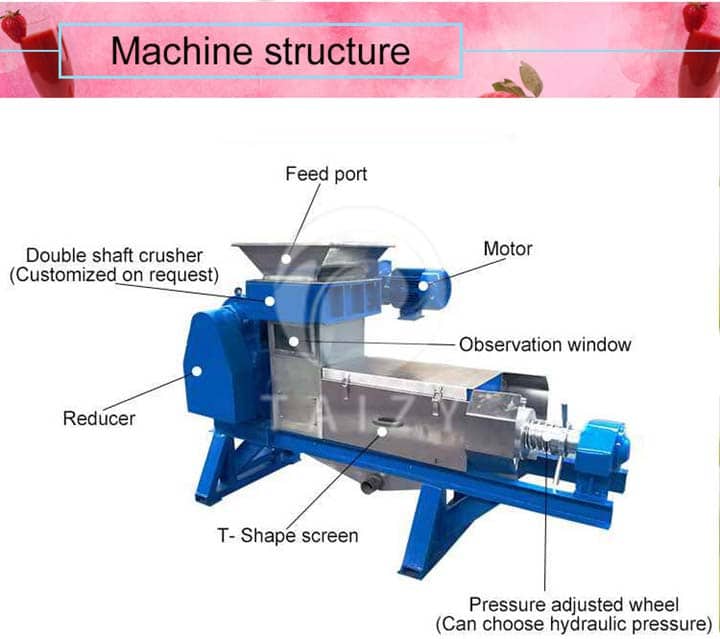

The commercial pomegranate juicer consists of front support, feed hopper, spiral, filter net, rear support, slag tank, and other parts.

The fruit juice extractor machine is a crushing screw press spiral juicer. Some materials need to be crushed juicing. After the material enters the crushing box, the broken rod breaks the material by high-speed rotation. Then the broken material enters the press part through the stencil. The conveying screw pushes the material in the tank to the pressing screw. The pitch of the pressing screw is reduced and the shaft diameter is increased. The liquid contained in the material is squeezed out under the action of the resistance of the screen wall and the cone. The extruded liquid flows out of the sieve hole.

Pomace after pressing is discharged outside the spiral juicer through the end of the sieve drum and the cone. There is a spring loaded on the back of the cone. Adjusting the preload and position of the spring can change the magnitude of the exhaust resistance and the size of the slag outlet to adjust the dryness and wetness of the raw material.

Installation preparation of the twin screw fruit juicer machine

- This twin screw fruit juice squeezer equips with movable casters for easy movement but needs to be placed on a flat surface.

- Check whether all parts are completely intact and whether the fastening bolts and screws are loose.

- The reducer is filled with a sufficient amount of lubricating oil (see the instruction manual).

- Turn on the power, and pay attention to whether the direction of rotation of the spiral is correct. The screw juice extractor needs Idle for 30 minutes, check whether there are abnormal phenomena and sounds in each rotating part and whether the operation is stable.

- Before feeding, the parts to be contacted should be cleaned and dried, and the machine should be effectively grounded to prevent leakage accidents.

Customer use case of the fruit juice extractor machine

There is a customer from America named Mikael Dallaire. He wants to open a juice processing plant. He ordered a model TZ-3 spiral juicer and mainly processed pomegranate. He buys the pomegranate from the farmer and then processes it into juice. Now he has been processing the pomegranate on this machine. A few days ago, we received a reply from him saying that the machine is very easy to use, and he will order a bigger one in a while.

Technical parameters of the spiral juicer & screw juice extractor:

| Model | TZ-1.5 | TZ-3 | TZ-5 | TZ-10 | TZ-15 |

| Capacity | 0.2-1.5t/h | 0.5-2t/h | 2-6t/h | 3-10t/h | 5-16t/h |

| Power | 5.5kw | 7.5kw | 11kw | 18.5kw | 22kw |

| Screen diameter | 270mm | 360mm | 430mm | 510mm | 610mm |

| Size | 2200*600*900mm | 3500*700*1000mm | 3580*1000*1470mm | 3740*1100*1650mm | 4500*1100*1650mm |

| Weight | 650kg | 1200kg | 2550kg | 2950kg | 4200kg |

| Screen aperture | 1.5mm | 1.5mm | 2.0*40mm | 2.0*40mm | 2.0*40mm |

Advantages of fruit juicer machine

- Wide application. For a single screw juicer, it can press grapes, berries, cabbage, melon, aloe, Chinese medicine residue, and other fruits and vegetables. For a double screw juicer, it is suitable for grapes, dregs, sugar cane, pulp, and vegetables, plant leaves, etc.

- High pressing rate. The pressing force on the raw material is large and uniform, with the compact structure of the screw, the final juice won’t contain any residue and slag.

- Four screw regulating handles can adjust the pressure.

- The best juicer machine is made of stainless steel with high strength.

- Good corrosion resistance and long service life.

- The driving unit adopts the shaft-mounted mode, which is stable and reliable and saves energy consumption.

- In addition to the inlet and outlet, the rest structure is sealed, which enables the machine clean and hygienic.

- Simple structure, small floor space, easy installation, and maintenance.

- The slag body is controlled by a hydraulic cylinder (spring), and the oil pressure (spring) is adjustable.

Type three: special design fruit juice extractor machine

The special design juicer machine is designed by our company according to the German single screw press technology. It bears the advantages of single and double screw presses. Its working principle is to change the diameter of the sieve barrel, the shape of the screw, and rotation speed to press the raw material with different shapes, especially the materials containing colloidal proteins, oils, and fats. Thus, it has wide application, and almost meets the demand of all industries requiring the “solid-liquid separation”.

Compared with the horizontal screw machine, filter press, and vacuum suction filter, this screw juicer has steady performance and high working efficiency. It is widely used in pressing juice industries as well as chemical industries and environmental protection industries. The water content of the output is less than 60% (differs depending on the material).

Technical parameter of fruit juicing machine

| Model | ZKY-T1 | ZKY-T2 | ZKY-T3 | ZKY-T4 | ZKY-T55 | ZKY-T6 |

| Capacity | 0.8-1t/h | 1-1.5t/h | 3t/h | 5t/h | 10t/h | 20t/h |

| Power | 4kw | 7.5kw | 15.5kw | 18.5kw | 22kw | 30kw |

| Dimension | 1950*510*740 | 2400*600*1100 | 4100*850*1500 | 4900*920*1700 | 5200*1000*1870 | 6500*1200*2000 |

| Weight | 230kg | 1200kg | 2400kg | 3000kg | 3700kg | 5000kg |

Application of fruit juicer machine

- Vegetable: Jujube, sweet potato, potato

Plant roots: stems, leaves, etc.

Fruit: pineapple, apple, pear, blueberry, and other berries.

Flowers: peony, rose, etc.

- Dehydration of various waste residues such as copra, various Chinese medicine residues, tea leaves residues, cassava, slag, coffee residue, corn husk, fish carp, shrimp residue, chicken slag, etc.

- Kitchen waste, domestic garbage, and vegetable market waste, as well as the separation of fermented food waste, and biogas residue.

- Dehydration of various feces, such as pig manure, cow dung, duck dung, etc. (solid and liquid).

- medical plastics slag and gelatin slag, sludge residue.

Advantage of fruit juice extractor machine

- The propeller inside the screw juicer not only prevents the phenomenon of returning material but also plays the role of slight crushing. It can integrate the crushing and pressing at the same time, saving space and investment.

- The general screw juice making machine relies on the front material to push the back material to dewater, which requires the gap between the material and the spiral, the material and the material, and the material and screen to have enough friction, otherwise, there will be slipping and the raw material can not fully enter the juicer machine.

- All those factors will trigger the slag after pressing will be too wet or too dry, which is difficult to control. Our screw juicer adopts a forced feeding plate with a special structure and a spiral blade device to achieve smooth conveying of materials and uniform dryness of the pressing.

- The handwheel can adjust the wetness and dryness of the output. (it is unnecessary to adjust during the operation, and the medium and large juicing machine is hydraulically controlled. The working state is stable after optimizing, and it is easy to press and dewater.

- The press screw consists of a conveying screw and a pressing screw, and it is possible to design many pressing screws in series to achieve stepwise pressing that makes dehydration more thorough.

- The inside of the pressing screw is equipped with a stirrer, and the mixture is squeezed while being pressed to prevent the outer part is drying and the inner part is wet when the screw

- diameter is larger than 500 mm

- According to the needs, the press can realize steam, hot water, solvent, ethanol, etc. in the inside while pressing

- The press screen has two halves of the sieve and a reinforced sieve bucket for easy disassembly and cleaning.

- Two fruit juicer machines can be connected in series to get high-quality juice.

- The screw adopts precise machining precision, which makes the press screen bear self-cleaning function and is not easy to be blocked.

- Simple structure and reasonable design, German transmission technology, high torque, low noise, no vibration, fewer parts to be driven, fewer consumable parts to be replaced, and low maintenance costs.

- Stainless steel trapezoidal filter has high strength, wear resistance, durability, corrosion resistance, long service life, and good filtration performance.

- The special design screw enables the pressing speed to be fast, and the reverse flow is small.

- Different materials use different feeding screws, conveying screws, press screw lengths, curvatures, and thrusters.

FAQ of fruit juice extractor machine

for type three

- What is the raw material?

The raw materials are various such as flowers, fruit, vegetable, waste residues, etc.

- Can I place two juicer machines in series?

Yes, by doing this, the raw material can be juiced twice, getting cleaner juice.

- How many models do you have

Until now, we have 6 models, and their capacities are 0.8-1t/h, 1.5t/h, 3t/h, 5t/h, 10t/h, 20t/h.

for type one and type two

- Can I press twice if the output still contains some juice?

Yes, of course.

- How can I choose the best juicer machine?

It should be based on the raw material you want to press. If your raw material contains fewer plants, then it is better to buy a single screw juicer machine.

- Does the residue enter the final juice?

No, only the can pass through the screw due to its compact structure.

- Is the pressure adjustable?

Yes, it is adjustable.

- How can I clean the screen?

A high-pressure hydraulic giant can directly clean it.

Add Comment