The smart egg printer machine automatically prints the code on the eggs. The printed logo can be in various forms such as numbers, logos, production dates, and expiration dates. The ink sprayed on the eggs adopts edible ink, which is safe and hygienic. The egg code inkjet printing machine can be used alone or in combination with other egg processing machines. Coding on eggs meets the needs of consumers for dietary safety and traceability of egg production sites. And meet local laws and regulations, brand differentiation management. Now many egg processing factories use intelligent egg code printing machines to print code.

What is an egg printer machine?

Have you ever seen an egg with a spray code? The code on the egg may be the production date, the manufacturer’s name, logo, Chinese characters, or even a QR code. These coded eggs are sprayed on with an egg printer. The egg inkjet printer is such a machine that uses ink to spray the information that the manufacturer wants to carry on the egg.

Why use an egg printer machine to code?

It is a common practice to code on eggs. So why are these egg suppliers keener to code their eggs?

- Meet the laws and regulations.

Over the years, some countries in Europe have required the coding of eggs. Now, many national governments have clear requirements for egg coding. Egg coding not only meets domestic food safety requirements but also meets the requirements of exporting to other countries.

- Consumers pay attention to dietary health

Consumers’ increasing food safety and hygiene requirements are also one of the reasons for egg suppliers to spray codes on eggs. The production date and manufacturer sprayed on the eggs can make consumers clear about the freshness of the eggs and the manufacturer, and increase consumer confidence.

- Brand differentiation

The contrast between the coding on the eggs and the regular eggs makes the coding eggs stand out from the many regular eggs. And spraying the manufacturer’s logo on the eggs will also help to enhance the company’s brand.

- Demonstrate egg quality

Coding on eggs or traceable egg production sites, processing methods, sales channels, etc. This allows consumers to track the egg processing process and form an oversight role. In order to ensure the quality of the eggs, the quality of the eggs is manifested to a certain extent.

Egg code inkjet printing machine running video

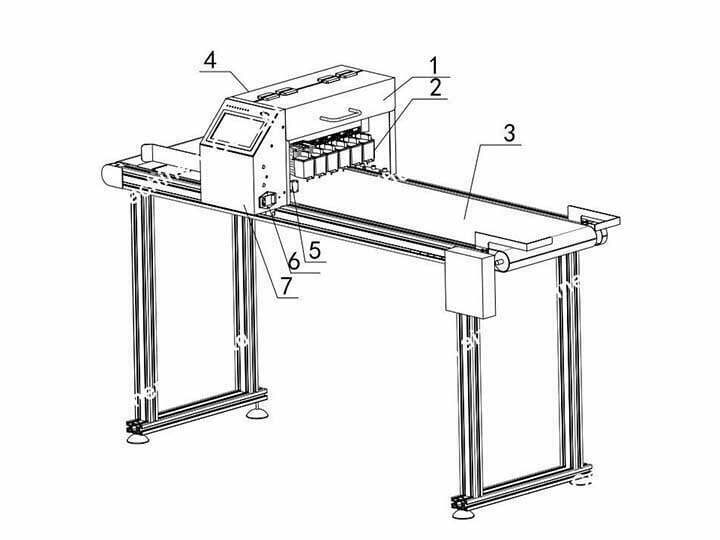

Automatic egg printer machine structure diagram

| 1. Main case front cover | 2. Print Head | 3 .conveyor belt |

| 4. Main case back cover | 5. photoelectric sensor | 6. main switch |

| 7.control enclosure |

As shown in the figure and label, the egg code printer machine mainly consists of 7 parts. Among them, there are three parts: a photoelectric sensor, a print head, and a conveyor belt which play a key role.

When the conveyor belt conveys the eggs to the egg printing machine, the photoelectric sensor senses the arrival of the eggs. The print head is prompted to print by an intelligent sensing system.

Coding style selection

The automatic egg printer machine can print date, time, shelf life, expiration date, serial number, logo, Chinese characters, numbers, barcodes, two-dimensional codes, etc.

About printing inks

Since the ink is directly spray-printed on the shell of the egg, and eggs are an essential ingredient every day, the safety of the ink needs to be guaranteed. Taizy smart egg inkjet printer uses European standard edible ink. After printing, the logo is recognizable and easy to clean. While ensuring the printing effect, it also ensures the health of eating.

Matters needing attention when using an egg printer machine

- The machine should be used in a normal temperature and dry environment to ensure the cleanliness of the machine and avoid electromagnetic interference;

- When replacing the ink cartridge, the device should be turned off, and the ink and cleaning fluid should be prevented from entering the mouth and eyes. In case of accidental contact with eyes, rinse with plenty of water.

- The automatic egg inkjet printer is compact in structure and precise in design. If it fails, you should ask a professional to repair it.

- The machine is generally matched with special ink and cleaning fluid. It is best to replace the same ink and cleaning fluid after use to avoid problems.

- Static electricity will damage the device, please discharge the static electricity before using the device.

Egg code printing machine configuration selection

Taizy recommends three egg coding configurations depending on the customer’s throughput.

- 6-head egg printer

The 6-head inkjet printer is mainly for the eggs that have been packaged in the egg tray. It can spray code on a row of 6 eggs at one time, with rapid coding and large production volume.

- Mobile inkjet printer

The movable printer has only one nozzle. When printing, it prints each egg in turn from left to right. The speed of printing is slower than that of 6-head inkjet printers. This machine is suitable for egg printing in egg processing plants with smaller processing volumes.

- Egg printer + egg production line

If you run a large egg processing plant then I recommend you buy an egg printer machine and egg processing line. The egg processing production line includes cleaning, drying, grading, coding, and other processes.

Taizy food machinery manufacturer not only provides a single egg code inkjet printing machine, but also the whole egg processing line. If you want egg handling equipment, please contact us.

Add Comment