Red sausage is also named as smoke sausage, it is very common in the market. And people prefer to eating it in daily life. How to make sausage at home? The sausage production process is very easy, and today I will share the recipe and the steps for you.

Sausage Recipe

500g square pork, 226g fat pork, 250g beef, 38g starch, 3.6g soy protein powder, 35g salt, 6.6g Ajinomoto, 0.9g pepper, 0.1g sodium nitrite, 292g water.

Raw materials and tools

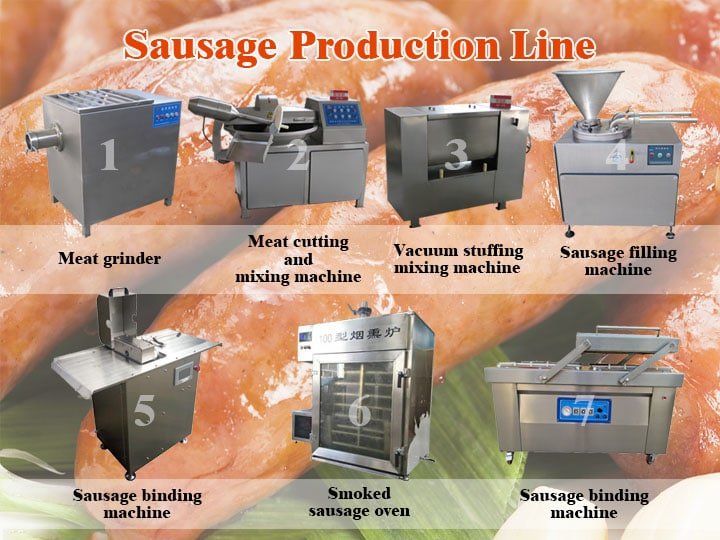

Pork, water, casing, meat grinder, meat cutting and mixing machine, sausage machine, baking oven, refrigerator, venting needle, knives, pickling box, stainless steel basin, cotton thread, platform scale, induction cooker, smoker furnace, etc.

Note: Fresh and frozen pork that has passed the hygienic inspection is required. You shall cut the clean pock into small pieces, and the size of them should be about 5 to 6 cm.

Pickle

- Mix salt with the meat and quickly put them into the container, and store it in the pickling room at 2~4 °C for about 72 hours.

- The surface of the meat piece and the cut surface are all turned into bright colors, and they are solid and elastic. Pickled fat, usually with large pieces of fat, can also bepeeled fat blocks.

- Mix the fine salt and sodium nitrate (50kg fat and about 25g sodium nitrate) on the pock fat by hand. When the surface is evenly covered with a crystalline salt layer, you shall immediately move it into 2 ~4 ° C pickling room.

- After 3 to 5 days, the fat became firm, and you can cut the meat to check if the color of the deep layer and the outer surface are consistent.

Grinding meat

Put the lean meat into a meat grinder, and the diameter is 2 to 3 mm.

Mixing the stuffing

- Cut the garlic into pieces

- Cut the fat pieces into1cm squares.

- Add 25% to 30% of water to the starch, remove the impurities floating and sinking at the bottom.

- Pour the starch slurry into the minced pork.

- Mix the meant square with pepper.

- The meat filling temperature is around 10 °C.

Filling

Wash the inside and outside of the casing, control the moisture, and eliminate the odor. After the meat is poured into the casing, it is tied with cotton thread. After filling the stuffing, you need to unscrew the knot and puncture the intestines to make the red sausages dry.

Baking

- Hanging the red sausage on the wooden pole, the distance between the sausage and sausage is 3~4cm.

- the temperature of the lower layer of the red sausage should be kept at 65~85°C, and the baking time is 1h.

- The baking is finished if the casing is dry, and the sausage surface shows translucent without the sticky feeling. At the same time, the meat is rosy without oil near the front sausage.

Boiling

- The water temperature must reach 85 to 90 °C.

- The constant temperature in the pot should be kept at 80-83 °C, and the boiling time is20-30 min.

- The temperature of the center of each sausage is 72 °C or higher. Generally, all is finished if the sausage is hard and the elasticity is sufficient.

Cooling

Put the cooked red sausage in a ventilated environment.

Smoking

- Place the firewood on the bottom, and cover with a layer of wood chips

- The ratio of firewood and wood chips is 1:2.

- Put the cooked red sausage into the furnace, ignite the woodpile, and close the door to

- Keep the oven at 35~45°C for 12h.

As for the sausage production line, we have professional processing machines, please contact us to know more.