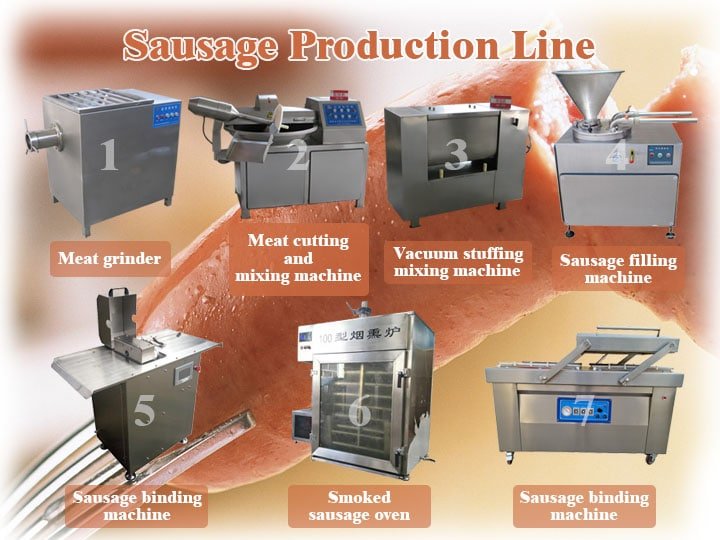

The sausage machine is used to produce sausages. The whole process is automatic, saving a lot of time and energy. It includes seven machines such as a meat grinder, a meat cutting and mixing machine, a stuffing mixer, a sausage filling machine, a sausage binding machine, a smoked sausage oven, and a vacuum packaging machine.

150kg/h sausage production line machine list and parameters

| Machine | Capacity(kg / h) | Power(kW) | Size(mm) | Weight(kg) |

| Meat grinder | 300-500 | 4 | 950 * 550 * 1050 | 240 |

| meat cutting machine

|

150-200 | 5 | 780 * 600 * 850 | 300 |

| sausage mixing machine | 160 | 2.2 | 1350 * 820 * 1350 | 400 |

| sausage filling machine

|

300 | 0.75 | 530 * 410 * 1350 | 120 |

| sausage binding machine | 10〜100Knots/minute adjustable | Manual crank | 650 * 550 * 450 | 18 |

| smoked sausage oven

|

150 | 6(steam) | 1700 * 1300 * 2400 | |

| sausage packaging machine

|

2-5batch/min | 2.5 | 1680 * 780 * 1000 | 480 |

Sausage production line working video

Meat grinder

The meat grinder is the first step of the sausage production line. It cuts the meat into pellets of different specifications. The raw material can be fresh meat or frozen meat below -18°C. The meat grinder will not damage the muscle fiber tissue of the meat, and the temperature rise of the meat is small, which is conducive to preservation. It can maintain the nutrition and fresh taste of the meat and reduce the loss of protein.

The diameter of the orifice plate of the meat grinder can be customized according to the customer’s finished product requirements. We can customize orifice plates with a diameter of 4-15mm.

Meat cutting mixer

The meat cutting mixer can cut the meat into a delicate state and mix other ingredients evenly. Such an operation can prevent muscle myoglobin, fat and other nutrients from being oxidized and destroyed, thereby retaining the original color, fragrance, taste, and various nutrient content. This machine can improve the fineness of meat and increase elasticity by cutting and mixing.

Sausage mixing machine

Vacuum stuffing mixing machine is mainly used for sausages and is also the preferred equipment for producing quick-frozen foods. Through the vacuum negative pressure, the food stuffing, meat stuffing are fully expanded with good elasticity and bright color. In addition, there is no bubbles inside the meat. The unique blender can refine the minced meat. After the meat processing, the animal protein between the meat fibers can be freely precipitated, which can ensure that the meat is stirred evenly in a fluffy state. The added sauce can be fully absorbed, making the stuffing fluffy and tender. The machine is suitable for canteens, hotels, food processing plants, pharmaceutical plants, chemical plants,etc. The sausage processed by it is isolated from oxygen, reducing the growth of bacteria and improving the brittleness of the meat.

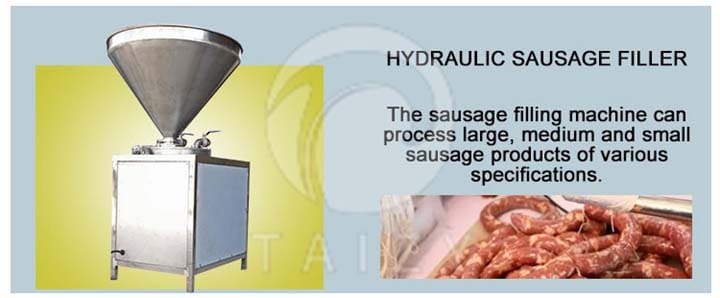

Sausage filling machine

The sausage filling machine is an indispensable equipment in the sausage maker. It can fill large, medium, and small size sausage with various specifications, widely applying to fill animal casings, protein casings, and plastic casings. Sausage filling machine is easy to operate, and all parts are made of stainless steel with safe and hygienic features. Large capacity hopper makes it efficient and fast. It is also equipped with a transfer switch, double pedal control.

Sausage binding machine

Sausage binding machine is to bind the wires between the sausages and fully separate them. It adopts the hand-crank design, automatically binding the wires with high efficiency and fast speed.

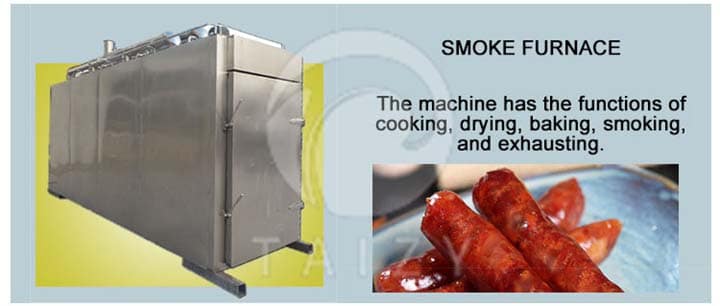

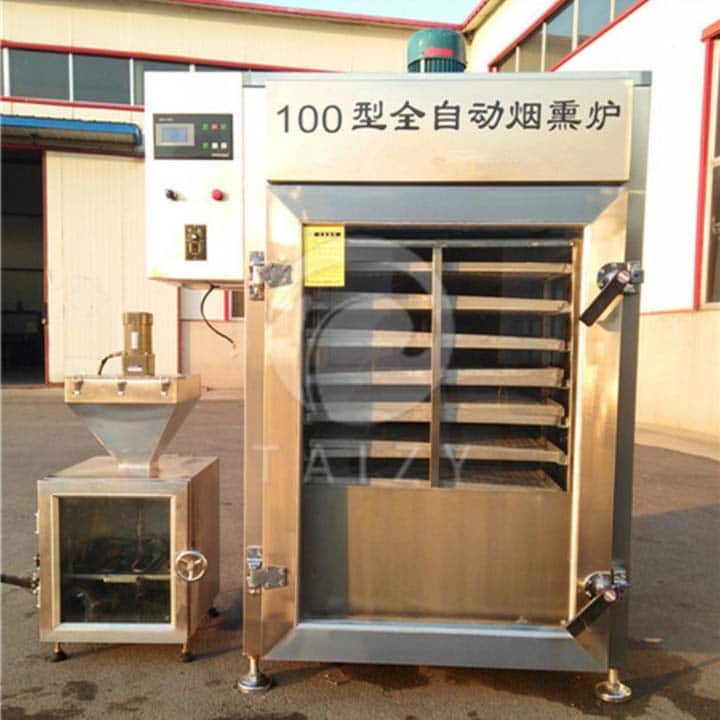

Smoked sausage oven

During the sausage maker, smoked sausage oven is to smoke the sausage, and it is an important part of the sausage production line. It has the functions of cooking, drying, baking, smoking, exhausting, cleaning, etc. The sausage smoked by it has a better taste.

Sausage packaging machine

The vacuum packaging machine is to vacuum and then seal the product so that the packaged items can oxygen isolation, moisture-proof, mildew-proof, rust-proof, anti-corrosion, insect-proof, anti-pollution, etc. Vacuum packaging machines can effectively extend the life and preservation period in order to store and transport. It is suitable for packing cooked food, medicine, chemicals, precision instruments, clothing, hardware products, electronic components, various solid, powder, liquid, etc.

Advantage of the sausage maker

- The processed sausage bears goods taste, and it is the best seller on the food market.

- The final sausage is intact with the same size.

- The whole sausage production line boasts stable performance and high capacity.

- Each machine has different models, and you can choose the proper one according to your need.

The sausage production line export to Australia

A customer from Australia who is engaged in the production of hamburger patties wants to expand the scope of production and business. He plans to open a sausage production line. And asked us in detail about our machine. We gave him detailed information about each machine and video of machine operation. The customer and his business partner studied our machine in detail and asked us about the cleaning details and voltage of the machine.

All the machines in the sausage processing machine are stainless steel and can be washed directly with water. And we can change the voltage of each machine according to the customer’s local voltage requirements. The voltage requirement of the customer is 480v 60hz, we confirm with our technicians, we can meet satisfied with it. In addition, he also needs a frozen meat dicing machine, stringing machine, meat stripping machine, and other machines. While discussing the machine in detail, the customer submitted the documents for purchasing the machine to the government. After obtaining the purchase approval, he placed an order directly with us.

FAQ of the sausage maker

1.What’s the raw material?

The raw material can be fresh meat or frozen meat.

2.What is the capacity of sausage maker?

We have different models for each machine,so the capacity range is large.

3.Must the sausage be smoked?

It depends on the customer’s production process.